ULE-5/12-D24P-C Murata Power Solutions Inc, ULE-5/12-D24P-C Datasheet - Page 17

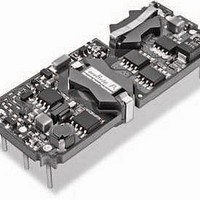

ULE-5/12-D24P-C

Manufacturer Part Number

ULE-5/12-D24P-C

Description

DC/DC Converters & Regulators 60W 24V to 5V 12A POSITVE POLARITY

Manufacturer

Murata Power Solutions Inc

Series

ULEr

Type

Step Downr

Specifications of ULE-5/12-D24P-C

Output Power

60 W

Input Voltage Range

18 V to 36 V

Input Voltage (nominal)

24 V

Number Of Outputs

1

Output Voltage (channel 1)

5 V

Output Current (channel 1)

12 A

Isolation Voltage

2.25 KV

Package / Case Size

Eighth Brick

Product

Isolated

Output Current

12A

Input Voltage

24V

Output Voltage

5V

Screening Level

Industrial

Product Length (mm)

58.4mm

Product Depth (mm)

22.9mm

Mounting Style

Through Hole

Pin Count

8

Package / Case

1/8-Brick

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

ULE-5/12-D24P-C

Post Refl ow Procedures

After successful solder refl ow, be sure to completely clean and dry your assem-

bled boards using a recommended wash solution and dryer. Failure to remove all

fl ux may cause long term deterioration of on-board conductors and components.

And, traces of contaminants which are not removed may reduce isolation volt-

ages or risk a safety hazard. Be aware that low remaining concentrations of fl ux

or other assembly compounds can be very diffi cult to detect by eye.

Pick and Place pcb Mounting

The main issues here are pad area, orientation, positioning accuracy, vacuum

pickup and coplanarity. Murata Power Solutions recommends that pcb pads to

interface with the DC/DC converter should be sized as shown in the diagram

below. The pads footprint accommodates the positioning accuracy of your SMT

equipment and manufactured tolerances of the DC/DC mounting leads.

250

200

150

100

50

0.130 TYP.

(3.30)

SMT UNIT

0.020 (0.51)

Figure 12. Recommended SMT Mounting Pad Dimensions

(When the Heat-shield temperature exceeds +250°C,

Z1

100

Z2

Figure 11. Recommended Solder Profi le

DIMENSIONS ARE IN INCHES (MM)

0.300 TYP.

Z3

(7.62)

the air within is 50°C cooler)

2.340 (59.44)

1.975 (50.17)

200

PCB

Z4

Z5

SMT LEAD

Z6

300

0.150 TYP.

(3.81)

Z7

Seconds

Copper Pad

400

www.murata-ps.com

500

0.020 REF.

(0.51)

0.183

(4.65)

Heat Shield

Test Board

Air Under Shield

600

viewable by your SMT imaging system. Observing from the bottom, your SMT

imaging camera should fi nd these marks to identify the converter and verify pin

1. On most pick-and-place systems, during head transit, the imaging system will

automatically fi ne tune the end mounting position of the converter using image

comparisons from these fi ducials or other reference marks you have chosen.

systems have a one inch or less observing area since most SMT parts are con-

siderably smaller than these converters. You may prefer to train your imaging

system to use a corner of the converter or an I/O lead.

In the remote possibility that the fi ducials may have changed position with a PC

board revision, you should not mix different date lots on any one production as-

sembly session. In addition, to avoid non-recognition or misplacement of the con-

verter, retrain your imaging system at the beginning of each series of assembly

sessions. There may be tiny variations in the absolute position from unit to unit.

not rely on the inkjet marking on the heat shield to verify proper orientation.

Use the pin 1 notch instead.

very fl at mounting leads (see coplanarity specs) however your host pcb must

also be fl at for a successful mounting. Be aware of possible warping of the pcb

under heat gradients and/or humidity conditions. The solder paste will tolerate

a small amount of mismatch and will tend to “wet” the entire pad area by

capillary action if the temperatures are correct.

for the weight and size of the DC/DC converter. Note that units with heatsinks

are slightly heavier. Tests at Murata Power Solutions have shown that excellent

acceleration and transit head speed are available for these converters if the

collet size is proper and the vacuum is suffi cient. When positioning the vacuum

collet, use the geometric center of the heat shield as the pickup area since the

center of gravity is very close.

Soldering

Refl ow technology works well for small parts. However, larger components

such as these DC/DC’s with higher thermal mass may require additional refl ow

time (but not enough to disturb smaller parts also being refl owed concurrently

with the DC/DC). When this is combined with higher temperature lead-free sol-

ders (or solders with reduced heavy metals), there is increased risk of reheat-

ing components inside the DC/DC enough so that they either change positions

(and possibly stop functioning) or the components are damaged by the heat.

On the bottom of the converter, the ULE series include optical fi ducial marks

The fi ducial marks are placed fairly close together because many imaging

The fi ducial marks will remain identical within any date code lot of converters.

If you use a camera above the pcb after placement on the solder paste, do

Coplanarity: Murata Power Solutions manufactures these converters with

Vacuum Pickup: Select the vacuum collet on your SMT placement system

are oriented in the same direction. See the diagram below. For

the ULE series, a notch is placed on the top of the case (on the

removal tabs) to indicate the pin 1 position. You should visually

inspect the tray to be sure of this orientation.

camera which must be trained to recognize the orientation of

the converter before it is assembled onto the host PC board.

This “training” locates and identifi es prominent, dimensionally

stable landmarks such as the board corners or fi ducial marks.

Orientation: When loaded into JEDEC trays, the converters

Most pick-and-place automatic assembly systems use a

Isolated, High Density, Eighth-Brick

11 May 2011

1.25–20 Amp, DC/DC Converters

MDC_ULE Series.E01 Page 17 of 26

email: sales@murata-ps.com

ULE Series