EP3SL150F780C4N Altera, EP3SL150F780C4N Datasheet - Page 410

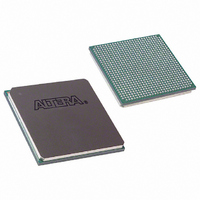

EP3SL150F780C4N

Manufacturer Part Number

EP3SL150F780C4N

Description

IC STRATIX III FPGA 150K 780FBGA

Manufacturer

Altera

Series

Stratix® IIIr

Datasheets

1.EP3SL150F780C4N.pdf

(16 pages)

2.EP3SL150F780C4N.pdf

(332 pages)

3.EP3SL150F780C4N.pdf

(456 pages)

4.EP3SL150F780C4N.pdf

(341 pages)

Specifications of EP3SL150F780C4N

Number Of Logic Elements/cells

142500

Number Of Labs/clbs

5700

Total Ram Bits

6390

Number Of I /o

488

Voltage - Supply

0.86 V ~ 1.15 V

Mounting Type

Surface Mount

Operating Temperature

0°C ~ 85°C

Package / Case

780-FBGA

Family Name

Stratix III

Number Of Logic Blocks/elements

142500

# I/os (max)

488

Frequency (max)

450MHz

Process Technology

65nm

Operating Supply Voltage (typ)

1.1V

Logic Cells

142500

Ram Bits

6543360

Operating Supply Voltage (min)

1.05V

Operating Supply Voltage (max)

1.15V

Operating Temp Range

0C to 85C

Operating Temperature Classification

Commercial

Mounting

Surface Mount

Pin Count

780

Package Type

FC-FBGA

For Use With

544-2568 - KIT DEVELOPMENT STRATIX III

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Number Of Gates

-

Lead Free Status / Rohs Status

Compliant

Other names

544-2403

EP3SL150F780C4NES

EP3SL150F780C4NES

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

EP3SL150F780C4N

Manufacturer:

ALTERA

Quantity:

3 000

- EP3SL150F780C4N PDF datasheet

- EP3SL150F780C4N PDF datasheet #2

- EP3SL150F780C4N PDF datasheet #3

- EP3SL150F780C4N PDF datasheet #4

- Current page: 410 of 456

- Download datasheet (7Mb)

13–12

Figure 13–9. SAMPLE/PRELOAD Shift Data Register Waveforms

Note to

(1) Data stored in boundary-scan register is shifted out of TDO.

(2) After boundary-scan register data has been shifted out, data entered into TDI will shift out of TDO.

Stratix III Device Handbook, Volume 1

Figure

TAP_STATE

TMS

TDO

TCK

TDI

13–9:

SHIFT_IR

Instruction Code

During the capture phase, multiplexers preceding the capture registers select the

active device data signals. This data is then clocked into the capture registers. The

multiplexers at the outputs of the update registers also select active device data to

prevent functional interruptions to the device. During the shift phase, the

boundary-scan shift register is formed by clocking data through the capture registers

around the device periphery and then out of the TDO pin. The device can

simultaneously shift new test data into TDI and replace the contents of the capture

registers. During the update phase, data in the capture registers is transferred to the

update registers. You can then use this data in the EXTEST instruction mode. Refer to

“EXTEST Instruction Mode” on page 13–13

Figure 13–9

instruction code is shifted in through the TDI pin. The TAP controller advances to the

CAPTURE_DR state and then to the SHIFT_DR state, where it remains if TMS is held

low. The data that was present in the capture registers after the capture phase is

shifted out of the TDO pin. New test data shifted into the TDI pin appears at the TDO

pin after being clocked through the entire boundary-scan register. If TMS is held high

on two consecutive TCK clock cycles, the TAP controller advances to the UPDATE_DR

state for the update phase.

EXIT1_IR

shows the SAMPLE/PRELOAD waveforms. The SAMPLE/PRELOAD

UPDATE_IR

SELECT_DR

CAPTURE_DR

Chapter 13: IEEE 1149.1 (JTAG) Boundary-Scan Testing in Stratix III Devices

(1)

for more information.

IEEE Std. 1149.1 BST Operation Control

SHIFT_DR

© July 2010 Altera Corporation

(2)

UPDATE_DR

EXIT1_DR

Related parts for EP3SL150F780C4N

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

CYCLONE II STARTER KIT EP2C20N

Manufacturer:

Altera

Datasheet:

Part Number:

Description:

CPLD, EP610 Family, ECMOS Process, 300 Gates, 16 Macro Cells, 16 Reg., 16 User I/Os, 5V Supply, 35 Speed Grade, 24DIP

Manufacturer:

Altera Corporation

Datasheet:

Part Number:

Description:

CPLD, EP610 Family, ECMOS Process, 300 Gates, 16 Macro Cells, 16 Reg., 16 User I/Os, 5V Supply, 15 Speed Grade, 24DIP

Manufacturer:

Altera Corporation

Datasheet:

Part Number:

Description:

Manufacturer:

Altera Corporation

Datasheet:

Part Number:

Description:

CPLD, EP610 Family, ECMOS Process, 300 Gates, 16 Macro Cells, 16 Reg., 16 User I/Os, 5V Supply, 30 Speed Grade, 24DIP

Manufacturer:

Altera Corporation

Datasheet:

Part Number:

Description:

High-performance, low-power erasable programmable logic devices with 8 macrocells, 10ns

Manufacturer:

Altera Corporation

Datasheet:

Part Number:

Description:

High-performance, low-power erasable programmable logic devices with 8 macrocells, 7ns

Manufacturer:

Altera Corporation

Datasheet:

Part Number:

Description:

Classic EPLD

Manufacturer:

Altera Corporation

Datasheet:

Part Number:

Description:

High-performance, low-power erasable programmable logic devices with 8 macrocells, 10ns

Manufacturer:

Altera Corporation

Datasheet:

Part Number:

Description:

Manufacturer:

Altera Corporation

Datasheet:

Part Number:

Description:

Manufacturer:

Altera Corporation

Datasheet:

Part Number:

Description:

Manufacturer:

Altera Corporation

Datasheet:

Part Number:

Description:

CPLD, EP610 Family, ECMOS Process, 300 Gates, 16 Macro Cells, 16 Reg., 16 User I/Os, 5V Supply, 25 Speed Grade, 24DIP

Manufacturer:

Altera Corporation

Datasheet: