STEVAL-CCH002V1 STMicroelectronics, STEVAL-CCH002V1 Datasheet - Page 36

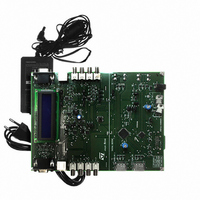

STEVAL-CCH002V1

Manufacturer Part Number

STEVAL-CCH002V1

Description

BOARD EVAL HDMI $ VIDEO SWITCH

Manufacturer

STMicroelectronics

Specifications of STEVAL-CCH002V1

Design Resources

STEVAL-CCH002V1 Gerber Files STEVAL-CCH002V1 Schematic STEVAL-CCH002V1 Bill of Material

Main Purpose

Video, HDMI and Video Switches

Embedded

Yes, MCU, 8-Bit

Utilized Ic / Part

STMAV335, STMAV340, STHDMI002A, STDVE003A

Primary Attributes

DVI-I, 2 HDMI, Y Pb Pr, S-Video, CVBS, VGA - Input and Output

Secondary Attributes

LCD Displays Selection Status of Video Switches and Buffers

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

497-8371

Application information

5

5.1

5.2

5.3

36/42

Application information

Power supply sequencing

Proper power-supply sequencing is advised for all CMOS devices. It is recommended to

always apply V

Power supply requirements

Bypass each of the V

device as possible, with the smaller-valued capacitor as close to the V

possible.

All V

from each V

variation can only be ±5% as per the HDMI specifications.

The maximum tolerable noise ripple on 3.3 V supply must be within a specified limit.

Differential traces

The high-speed TMDS inputs are the most critical parts for the device. There are several

considerations to minimize discontinuities on these transmission lines between the

connectors and the device.

(a) Maintain 100-Ω differential transmission line impedance into and out of the STDVE003A.

(b) Keep an uninterrupted ground plane below the high-speed I/Os.

(c) Keep the ground-path vias to the device as close as possible to allow the shortest return

current path.

(d) Layout of the TMDS differential inputs should be with the shortest stubs from the

connectors.

Output trace characteristics affect the performance of the STDVE003A. Use controlled

impedance traces to match trace impedance to both the transmission medium impedance

and termination resistor. Run the differential traces close together to minimize the effects of

the noise. Reduce skew by matching the electrical length of the traces. Avoid discontinuities

in the differential trace layout. Avoid 90 degree turns and minimize the number of vias to

further prevent impedance discontinuities.

CC

pins can be tied to a single 3.3 V power source. A 0.01 μF capacitor is connected

CC

CC

pin directly to ground to filter supply noise. The maximum power supply

before applying any signals to the input/output or control pins.

CC

pins with 0.1 μF and 1 nF capacitors in parallel as close to the

CC

pin of the device as

STDVE003A