RZB35DHHN Sullins Connector Solutions, RZB35DHHN Datasheet - Page 83

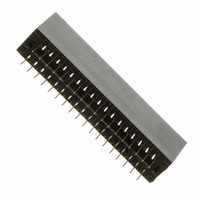

RZB35DHHN

Manufacturer Part Number

RZB35DHHN

Description

CONN EDGE DUAL .050 DIP 70 POS

Manufacturer

Sullins Connector Solutions

Datasheet

1.RZB13DHFR.pdf

(132 pages)

Specifications of RZB35DHHN

Card Type

Dual Edge

Card Thickness

0.062" (1.57mm)

Gender

Female

Number Of Positions

70

Pitch

0.050" (1.27mm)

Number Of Rows

2

Mounting Type

Through Hole

Contact Finish

Gold

Contact Finish Thickness

10µin (0.25µm)

Color

Black

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Features

-

Other names

S3127

PLATING - RoHS Compliant

INSULATOR MATERIAL

CONTACT CENTERS

NUMBER OF POSITIONS

READOUT

TERMINATION TYPE

See applicable specifi cation pages for more information.

Specifications are subject to change without notice.

* Requires ‘K’ Modifi cation Code

Platings that start with ‘E’ are for Economy Eyelet Only

Other Plating and thicknesses available upon request.

*EMPSL =

*MPSL =

*EMPL = .000100” Overall Pure Tin, Matte

EMPP = Spinodal Contact Material

02 - 70 Contacts Per Row

ALL PLATINGS ARE LEAD FREE AND HAVE

*MPL = .000100” Overall Pure Tin, Matte

All Materials are U.L. Approved 94V-0

100 = .100” [2.54mm]

125 = .125” [3.18mm]

150 = .150” [3.84mm]

156 = .156” [3.96mm]

MPP = Spinodal Contact Material

EMP = .000010” Overall Gold

WE = .025” Square Card Extender -

FS = .045” Square Tails - .720” Insulator Height

PE = Economy Eyelet - .431” Insulator Height,

SE = Card Extender - .431” Insulator Height

MP = .000010” Overall Gold

W = .025” Square Wire Wrap -

D = Dual Row

P = Solder Eyelet - .431” Insulator Height

R = .026” Round Tails - .610” Insulator Height,

S = Dip Solder - .431” Insulator Height

0 = PBT, Blue

1 = PPS, Brown

2 = PBT, Green

3 = PBT, Black

4 = PA9T, Black

5 = PPS, Black

6 = PPS, Green

7 = PPS, Brown

8 = Peek, Natural

www.sullinscorp.com

.000050” NICKEL UNDERPLATE

Contact Surface

(Overall Gold Only)

(Overall Gold Only)

Card Extender, .156” only

.610” Insulator Height

.610” Insulator Height

.000010” Gold .000100” Pure Tin Matte

.000010” Gold .000100” Pure Tin Matte

|

_ MP_ _ - 0 100 - 22 - D W - 5 xxx

Termination

760-744-0125

|

toll-free 888-774-3100

10 = One Ear, #4-40 Threaded Insert

11 = .142” Mounting Holes

12 = .128” Clearance Holes

13 = Flush Ears, .128” Clearance Holes

14 = .142” Side Holes (Cross Drilled)

15 = Flush Ears, .125” Clearance Holes

16 = Flush .250” Ears to top of the

18 = Flush Ears, .125” Side Holes

19 = .152” Clearance Holes

58 = Raised Ears, .125” Side Holes

81 = Flush Ears, .125” Side Holes

86 = Side Holes with #4-40 Threaded Insert

1 = .125” Clearance Holes

2 = #4-40 Threaded Insert

3 = Floating Bobbin

4 = No Mounting Ears

5 = Raised with .125” Clearance Holes

6 = Raised with #4-40 Threaded Insert

8 = .125” Side Holes (Cross Drilled)

9 = One Ear, .125” Clearance Hole

.245” Ears, .431” Insulator Height

.250” Flush Ears, .610” Insulator Height

.245” Ears, .431” Insulator Height

.250” Flush Ears, .610” Insulator Height

.220” Ears not Including Bobbin

on All Connectors

(Flush Ears on .610 Insulator Height )

Wire Wrap Only, .610” Insulator Height

Wire Wrap Only, .610” Insulator Height

Dip Solder & Eyelet

Dip Solder & Eyelet

.431” Insulator Height, Dip Solder, Eyelet

.610” Insulator Height, Wire Wrap

.431” Insulator Height, Dip Solder & Eyelet

.610” Insulator Height, Wire Wrap

.430” Ears with Pad on .610” Insulator

Height, Wire Wrap Only

.431” Insulator Height, Dip Solder, Eyelet

.610” Insulator Height, Wire Wrap

.190” Ears, No Pad

.610” Insulator Height, Wire Wrap Only

Card Entry Side of the Connector,

.610” Insulator Height, Wire Wrap Only

(Cross Drilled)

.610” Insulator Height, Wire Wrap Only

(Cross Drilled)

.250” Ears with Pad, .610” Insulator Height,

Wire Wrap

.250” Ears with Pad, .610” Insulator Height

All Connectors

MOUNTING STYLE

|

fax 760-744-6081

PART NUMBER OPTIONS

Micro Plastics Edgecards

|

info@sullinscorp.com

CONSULT FACTORY FOR OTHER OPTIONS

X9 = .200” Row Spacing for

E9 = .200” Row Spacing on .156”

F9 = 6.802” Cardslot and .200” Row

TT = No Standoffs

M = Pad on Bottom of Mounting Ears

D = .000050” Gold Plating -

Q = Right Angle Connector Contacts

A = Contacts Loaded one side only

G = .000030” Gold Plating

H = .190” Contact Length for .025”

N = Hi-light Contact ID on Bottom

U = .000020” Gold Plating

B = Center Barrier for 28/56 -

C = .030” Longer Cardslot and

K = MPSL - Selective Gold with Pure

P = Engraving Reversed

R = Right Angle Connectors

Y = Beryllium Copper Contacts

Z = Standoffs on .156” Wire Wrap

F = 6.802” Cardslot for 43/86

L = .140” Contact Length for

S = Shorter Overall Length

T = Center Standoffs Removed

J = Low Insertion Force

MODIFICATION CODE

.156” Dip Solder & Eyelet

Mounting Hole Centers for 22/44,

All .156” (Consult Factory)

(Consult Factory)

Contact Centers

.156” Eyelet & Wire Wrap Only

Spacing for 43/86 Dip Solder Only

Square & .026” Round Contacts

.250” Contact Length without

Standoffs

Tin, Matte Plating on Tails

MPL - Overall Pure Tin, Matte

.156” Dip Solder Only

for .156” , .431” Insulator Height,

Dip Solder & Eyelet Only

(Consult Factory)

(Consult Factory)

Untrimmed

(Requires ‘R’ Modifi cation Code)

.100” & .125” Wire Wrap Only

.100” & .156” Dip Solder Only

.250” Row Spacing for

.125” Dip Solder Only

83