LM2679T-3.3 National Semiconductor, LM2679T-3.3 Datasheet - Page 12

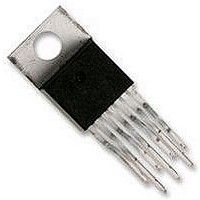

LM2679T-3.3

Manufacturer Part Number

LM2679T-3.3

Description

Power Supply IC

Manufacturer

National Semiconductor

Specifications of LM2679T-3.3

No. Of Outputs

1

No. Of Pins

7

Output Current

5A

Peak Reflow Compatible (260 C)

No

Output Voltage

3.3VDC

Termination Type

Through Hole

Leaded Process Compatible

No

Mounting Type

Through Hole

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

www.national.com

Application Hints

Using the nomographs and tables in this data sheet (or use

the available design software at http://www.national.com) a

complete step-down regulator can be designed in a few

simple steps.

Step 1: Define the power supply operating conditions:

Required output voltage

Maximum DC input voltage

Maximum output load current

Step 2: Set the output voltage by selecting a fixed output

LM2679 (3.3V, 5V or 12V applications) or determine the re-

quired feedback resistors for use with the adjustable

LM2679−ADJ

Step 3: Determine the inductor required by using one of the

four nomographs, Figure 3 through Figure 6 . Table 1 pro-

vides a specific manufacturer and part number for the induc-

tor.

Step 4: Using Table 3 (fixed output voltage) or Table 6 (ad-

justable output voltage), determine the output capacitance

required for stable operation. Table 2 provides the specific

capacitor type from the manufacturer of choice.

Step 5: Determine an input capacitor from Table 4 for fixed

output voltage applications. Use Table 2 to find the specific

capacitor type. For adjustable output circuits select a capaci-

tor from Table 2 with a sufficient working voltage (WV) rating

greater than Vin max, and an rms current rating greater than

one-half the maximum load current (2 or more capacitors in

parallel may be required).

Step 6: Select a diode from Table 5. The current rating of the

diode must be greater than I load max and the Reverse Volt-

age rating must be greater than Vin max.

Step 7: Include a 0.01µF/50V capacitor for Cboost in the de-

sign and then determine the value of a softstart capacitor if

desired.

Step 8: Define a value for R

rent limit to be at least 20% greater than Iout max to allow for

at least 30% inductor ripple current (

signs that must operate over the full temperature range the

switch current limit should be set to at least 50% greater than

Iout max (1.5 x I

FIXED OUTPUT VOLTAGE DESIGN EXAMPLE

A system logic power supply bus of 3.3V is to be generated

from a wall adapter which provides an unregulated DC volt-

age of 13V to 16V. The maximum load current is 4A. A soft-

start delay time of 50mS is desired. Through-hole compo-

nents are preferred.

Step 1: Operating conditions are:

Vout = 3.3V

Vin max = 16V

Iload max = 4A

Step 2: Select an LM2679T-3.3. The output voltage will have

a tolerance of

temperature range.

Step 3: Use the nomograph for the 3.3V device , Figure 3 .

The intersection of the 16V horizontal line (V

4A vertical line (I

tor, is required.

From Table 1, L46 in a through-hole component is available

from Renco with part number RL-1283-15-43.

±

2% at room temperature and

out

load

max).

max) indicates that L46, a 15µH induc-

ADJ

(Continued)

±

to set the peak switch cur-

3% over the full operating

±

15% of Iout). For de-

in

max) and the

12

Step 4: Use Table 3 to determine an output capacitor. With a

3.3V output and a 15µH inductor there are four through-hole

output capacitor solutions with the number of same type ca-

pacitors to be paralleled and an identifying capacitor code

given. Table 2 provides the actual capacitor characteristics.

Any of the following choices will work in the circuit:

2 x 220µF/10V Sanyo OS-CON (code C5)

2 x 820µF/16V Sanyo MV-GX (code C5)

1 x 3900µF/10V Nichicon PL (code C7)

2 x 560µF/35V Panasonic HFQ (code C5)

Step 5: Use Table 4 to select an input capacitor. With 3.3V

output and 15µH there are three through-hole solutions.

These capacitors provide a sufficient voltage rating and an

rms current rating greater than 2A (1/2 I

ing Table 2 for specific component characteristics the follow-

ing choices are suitable:

2 x 680µF/63V Sanyo MV-GX (code C13)

1 x 1200µF/63V Nichicon PL (code C25)

1 x 1500µF/63V Panasonic HFQ (code C16)

Step 6: From Table 5 a 5A or more Schottky diode must be

selected. For through-hole components only 40V rated di-

odes are indicated and 4 part types are suitable:

1N5825

MBR745

80SQ045

6TQ045

Step 7: A 0.01µF capacitor will be used for Cboost. For the

50mS softstart delay the following parameters are to be

used:

I

t

V

V

V

V

Using Vin max ensures that the softstart delay time will be at

least the desired 50mS.

Using the formula for Css a value of 0.148µF is determined

to be required. Use of a standard value 0.22µF capacitor will

produce more than sufficient softstart delay.

Step 8: Determine a value for R

current limit of at least 4A plus 50% or 6A.

Use a value of 6.2K .

ADJUSTABLE OUTPUT DESIGN EXAMPLE

In this example it is desired to convert the voltage from a two

battery automotive power supply (voltage range of 20V to

28V, typical in large truck applications) to the 14.8VDC alter-

nator supply typically used to power electronic equipment

from single battery 12V vehicle systems. The load current re-

quired is 3.5A maximum. It is also desired to implement the

power supply with all surface mount components. Softstart is

not required.

Step 1: Operating conditions are:

Vout = 14.8V

Vin max = 28V

Iload max = 3.5A

SST

SS

SST

OUT

SCHOTTKY

IN

: 50mS

: 16V

: 3.7µA

: 0.63V

: 3.3V

: 0.5V

ADJ

to provide a peak switch

load

max). Again us-