LM2402T National Semiconductor, LM2402T Datasheet - Page 4

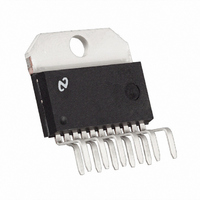

LM2402T

Manufacturer Part Number

LM2402T

Description

IC DRIVER MONOLITHIC TO-220-11

Manufacturer

National Semiconductor

Datasheet

1.LM2402T.pdf

(11 pages)

Specifications of LM2402T

Display Type

CRT

Current - Supply

27mA

Voltage - Supply

60 V ~ 85 V

Operating Temperature

-20°C ~ 100°C

Mounting Type

Through Hole

Package / Case

TO-220-11 (Bent and Staggered Leads)

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Interface

-

Configuration

-

Digits Or Characters

-

Other names

*LM2402T

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Part Number:

LM2402T

Manufacturer:

NS/国半

Quantity:

20 000

www.national.com

Theory of Operation

The LM2402 is a high voltage monolithic three channel CRT

driver suitable for very high resolution display applications,

up to 1600 x 1200 at 85 Hz refresh rate. The LM2402 oper-

ates using 80V and 12V power supplies. The part is housed

in the industry standard 11-lead TO-220 molded plastic

power package.

The simplified circuit diagram of one channel of the LM2402

is shown in Figure 1 . A PNP emitter follower, Q5, provides in-

put buffering. This minimizes the current loading of the video

pre-amp. R9 is used to turn off Q5 when there is no input.

This will drive the output stage to the V

power dissipation with no inputs. R6 is a pull-up resistor for

Q5 and also limits the current flow through Q5. R3 and R2

are used to set the current flow through Q1 and Q2. The ratio

of R1 to R2 is used to set the gain of the LM2402. R1, R2

and R3 are all related when calculating the output voltage of

the CRT driver. R

Q1 and Q2 are in a cascade configuration. Q1 is a low volt-

age and very fast transistor. Q2 is a higher voltage transistor.

The cascade configuration gives the equivalent of a very fast

and high voltage transistor. The two output transistors, Q3

and Q4, form a class B amplifier output stage. R4 and R5 are

used to limit the current through the output stage and set the

output impedance of the LM2402. Q6, along with R7 and R8

set the bias current through Q3 and Q4 when there is no

change in the signal level. This bias current minimizes the

crossover distortion of the output stage. With this bias cur-

rent the output stage now becomes a class AB amplifier with

a crossover distortion much lower than a class B amplifier.

Figure 2 shows a typical test circuit for evaluation of the

LM2402. Due to the very wide bandwidth of the LM2402, it is

necessary to use a FET probe that is DC coupled to the out-

put for evaluation of the CRT driver’s performance. The 50

resistor is used to duplicate the required series resistor in the

actual application. This resistor would be part of the arc-over

protection circuit. The input signal from the generator is AC

coupled to the input of the CRT driver.

Application Hints

INTRODUCTION

National Semiconductor (NSC) is committed to providing ap-

plication information that assists our customers in obtaining

the best performance possible from our products. The follow-

ing information is provided in order to support this commit-

ment. The reader should be aware that the optimization of

performance was done using a specific printed circuit board

designed at NSC. Variations in performance can be realized

due to physical changes in the printed circuit board and the

application. Therefore, the designer should know that com-

ponent value changes may be required in order to optimize

performance in a given application. The values shown in this

document can be used as a starting point for evaluation pur-

poses. When working with high bandwidth circuits, good lay-

out practices are also critical to achieving maximum perfor-

mance.

POWER SUPPLY BYPASS

Since the LM2402 is a very high bandwidth amplifier, proper

power supply bypassing is critical for optimum performance.

Improper power supply bypassing can result in large over-

shoot, ringing and oscillation. A 0.1 µF capacitor should be

connected from the supply pin, V

the supply and ground pins as is practical. Additionally, a

b

limits the current through the base of Q2.

CC

, to ground, as close to

CC

rail, minimizing the

4

10 µF to 100 µF electrolytic capacitor should be connected

from the supply pin to ground. The electrolytic capacitor

should also be placed reasonably close to the LM2402’s

supply and ground pins. A 0.1 µF capacitor should be con-

nected from the bias pin, V

tical to the part.

ARC PROTECTION

During normal CRT operation, internal arcing may occasion-

ally occur. Spark gaps, in the range of 200V, connected from

the CRT cathodes to CRT ground will limit the maximum volt-

age, but to a value that is much higher than allowable on the

LM2402. This fast, high voltage, high energy pulse can dam-

age the LM2402 output stage. The application circuit shown

in Figure 9 is designed to help clamp the voltage at the out-

put of the LM2402 to a safe level. The clamp diodes should

have a fast transient response, high peak current rating, low

series impedance and low shunt capacitance. FDH400 or

equivalent diodes are recommended. D1 and D2 should

have short, low impedance connections to V

respectively. The cathode of D1 should be located very close

to a separately decoupled bypass capacitor. The ground

connection of the diode and the decoupling capacitor should

be very close to the LM2402 ground. This will significantly re-

duce the high frequency voltage transients that the LM2402

would be subjected to during an arc-over condition. Resistor

R2 limits the arc-over current that is seen by the diodes while

R1 limits the current into the LM2402 as well as the voltage

stress at the outputs of the device. R2 should be a

carbon type resistor. R1 can be a

type resistor. Inductor L1 is critical to reduce the initial high

frequency voltage levels that the LM2402 would be sub-

jected to during an arc-over. Having large value resistors for

R1 and R2 would be desirable, but this has the effect of in-

creasing rise and fall times. The inductor will not only help

protect the device but it will also help optimize rise and fall

times as well as minimize EMI. For proper arc protection, it is

important to not omit any of the arc protection components

shown in Figure 9 . The values of L1 and R1 may need to be

adjusted for a particular application. The recommended mini-

mum value for R1 is 43 , with L1 = .049 µH.

OPTIMIZING TRANSIENT RESPONSE

Referring to Figure 9 , there are three components (R1, R2

and L1) that can be adjusted to optimize the transient re-

sponse of the application circuit. Increasing the values of R1

and R2 will slow the circuit down while decreasing over-

shoot. Increasing the value of L1 will speed up the circuit as

well as increase overshoot. It is very important to use induc-

tors with very high self-resonant frequencies, preferably

above 300 MHz. Air core inductors from J.W. Miller Magnet-

ics (part #75F518MPC) were used for optimizing the perfor-

FIGURE 9. One Channel of the LM2402 with the

Recommended Arc Protection Circuit.

BB

, to ground, as close as is prac-

1

⁄

4

W metal or carbon film

CC

and ground

1

DS101016-10

⁄

2

W solid