LT1580CT Linear Technology, LT1580CT Datasheet - Page 11

LT1580CT

Manufacturer Part Number

LT1580CT

Description

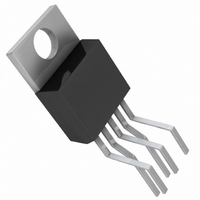

IC LDO REGULATOR 7A ADJ TO220-5

Manufacturer

Linear Technology

Datasheet

1.LT1580CTPBF.pdf

(16 pages)

Specifications of LT1580CT

Applications

Converter, Intel Pentium®

Voltage - Input

1.79 ~ 6 V

Number Of Outputs

1

Voltage - Output

1.25 ~ 4.65 V

Operating Temperature

0°C ~ 125°C

Mounting Type

Through Hole

Package / Case

TO-220-5 (Bent and Staggered Leads)

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

LT1580CT

Manufacturer:

LT

Quantity:

5 510

Part Number:

LT1580CT

Manufacturer:

LT/凌特

Quantity:

20 000

Part Number:

LT1580CT#PBF

Manufacturer:

LINEAR/凌特

Quantity:

20 000

Company:

Part Number:

LT1580CT7-2.5

Manufacturer:

LT

Quantity:

5

Company:

Part Number:

LT1580CT7-2.5

Manufacturer:

LT

Quantity:

5 510

Part Number:

LT1580CT7-2.5

Manufacturer:

LINEAR/凌特

Quantity:

20 000

APPLICATIONS

low dropout applications the power dissipation will be less

than 12W.

The power in the device is made up of two main compo-

nents: the power in the output transistor and the power in

the drive circuit. The additional power in the control circuit

is negligible.

The power in the drive circuit will be equal to:

where I

I

I

I

Characteristics curves.

The power in the output transistor is equal to:

The total power is equal to:

Junction-to-case thermal resistance is specified from the

IC junction to the bottom of the case directly below the die.

This is the lowest resistance path for heat flow. Proper

mounting is required to ensure the best possible thermal

flow from this area of the package to the heat sink. Thermal

compound at the case-to-heat sink interface is strongly

recommended. If the case of the device must be electroni-

cally isolated, a thermally conductive spacer can be used

as long as the added contribution to thermal resistance is

considered. Please consult Linear Technology’s “ Mount-

ing Considerations for Power Semiconductors,” 1990

Linear Applications Handbook, Volume 1 , Pages RR3-1 to

RR3-20. Note that the case of the LT1580 is electrically

connected to the output.

OUT

CONTROL

CONTROL

P

P

P

DRIVE

OUTPUT

TOTAL

/58 (max).

CONTROL

vs I

= (V

is a function of output current. A curve of

= P

= (V

OUT

DRIVE

CONTROL

POWER

is equal to between I

can be found in the Typical Performance

U

+ P

OUTPUT

– V

– V

INFORMATION

U

OUT

OUT

)(I

)(I

OUT

CONTROL

W

)

OUT

)

/100 (typ) and

U

The following example illustrates how to calculate

maximum junction temperature. Using an LT1580 and

assuming:

V

V

V

T

Power dissipation under these conditions is equal to:

Junction temperature will be equal to:

For the Control section:

For the Power section:

In both cases the junction temperature is below the

maximum rating for the respective sections, ensuring

reliable operation.

A

CONTROL

POWER

OUT

CASE-HEATSINK

Total Power Dissipation = P

P

I

P

P

Total Power Dissipation = 4.05W

T

T

93 C < 125 C = T

T

101 C < 150 C = T

= 70 C,

CONTROL

J

J

J

DRIVE

DRIVE

OUTPUT

= 70 C + 4.05W (4 C/W + 1 C/W + 2.7 C/W) = 101 C

= 70 C + 4.05W(4 C/W + 1 C/W + 0.65 C/W) = 93 C

= 2.5V, Iout = 4A,

= T

(max continuous) = 3.465V (3.3V + 5%),

A

= (V

= (5.25V – 2.5V)(69mA) = 190mW

(max continuous) = 5.25V (5V + 5%),

+ P

= (V

= ( 3.465V – 2.5V)(4A) = 3.9W

= I

HEATSINK

TOTAL

CONTROL

OUT

= 1 C/W (with thermal compound)

POWER

/58 = 4A/58 = 69mA

(

JMAX

JMAX

= 4 C/W,

HEATSINK

LT1580/LT1580-2.5

– V

– V

for Control Section

OUT

OUT

for Power Section

) (I

)(I

DRIVE

+

OUT

CONTROL

CASE-HEATSINK

)

+ P

OUTPUT

)

+

11

JC

)