EK61 Cirrus Logic Inc, EK61 Datasheet - Page 2

EK61

Manufacturer Part Number

EK61

Description

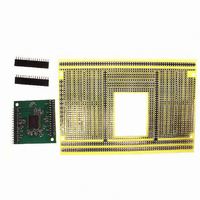

KIT EVALUATION PA78/PA79

Manufacturer

Cirrus Logic Inc

Series

Apex Precision Power™r

Specifications of EK61

Channels Per Ic

1 - Single, 2 - Dual

Amplifier Type

Power

Output Type

Single-Ended

Board Type

Bare (Unpopulated)

Utilized Ic / Part

PA78DK, PA79DK

Product

Amplifier Modules

Description/function

Audio Amplifiers

For Use With/related Products

PA78DK, PA79DK

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Operating Temperature

-

Current - Output / Channel

-

Voltage - Supply, Single/dual (±)

-

-3db Bandwidth

-

Slew Rate

-

Current - Supply (main Ic)

-

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Contains lead / RoHS non-compliant

Other names

598-1398

EK61

EK61

EK61

BEFORE YOU GET STARTED

• All Apex Precision Power

• Review the Apex Precision Power

• Always provide the appropriate heat sinking. Power dissipation must be considered to ensure maximum junction

• Always use adequate power supply bypass capacitors, Apex Precision Power

• Do not change connections while the circuit is powered

• In case -Vs is disconnected before +Vs, a diode between -Vs and ground is recommended to avoid damage.

• Initially set all power supplies to the minimum operating levels allowed in the product datasheet.

• Check for oscillations up to and above the unity gain bandwidth of the amplifier.

ASSEMBLY

The PA78DK & PA79DK are surface mount device and should be assembled to the EVAL61 substrate using surface

mount processes. Solder paste may be dispensed or screen-printed on the DUT pads. The heat slug on the back

of the PA78DK & PA79DK provides maximum heat dissipation capabilities when soldered to the foil footprint area.

The PA78DK & PA79DK should be reflowed to the substrate using a solder reflow furnace. If this is not available, a

heat plate capable of solder reflow temperatures may be used.

In accordance with the PA78DK and PA79DK datasheets, the package tab must be connected to a stable voltage

reference in order to achieve high slew rates. Jumpers J1 and J2 allow convenient connection of the tab to -Vs or

GND, respectively. Connect only one jumper to avoid a short circuit of the power supply.

Once the amplifier is mounted on the top of the substrate, the heat sink fan or selected heat sink can then be

mounted to the back of the substrate. A heat sink is not supplied with the kit, but several options are available

through AAVID Thermal Product, Inc. High thermal conductive thermal grease should be used when mounting the

heat sink fan or heat sink to the evaluation board.

Review Figure 3 on next page for other possible assembly methods to construct this evaluation kit.

NOTE: All grounds must be tied together on the EVAL36 board.

2

temperature (T

amp of output current.

J

) is not exceeded.

TM

amplifiers should be handled using ESD precaution.

TM

product datasheet and operating conditions.

Figure 2 - Schematic

P r o d u c t I n n o v a t i o n F r o m

TM

recommends at least 10µF per

EK61U