MS5540-CM Measurement Specialties Inc., MS5540-CM Datasheet - Page 17

MS5540-CM

Manufacturer Part Number

MS5540-CM

Description

MODULE BAROMETER MINITURE SENSOR

Manufacturer

Measurement Specialties Inc.

Datasheet

1.MS5540-CM.pdf

(18 pages)

Specifications of MS5540-CM

Pressure Type

Absolute

Operating Pressure

0.15 ~ 0.16 PSI, 10 ~ 1100 mbar

Output

Digital

Voltage - Supply

2.2 V ~ 3.6 V

Termination Style

PCB

Operating Temperature

-40°C ~ 85°C

Package / Case

6.2 x 6.4mm Module

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

223-1098-2

ASSEMBLY

MECHANICAL STRESS

It is recommended to avoid mechanical stress on the PCB on which the sensor is mounted. The thickness of the

PCB should not be below 1.6 mm. A thicker PCB is stiffer creating less stress on the soldering contacts. For

applications where mechanical stress cannot be avoided (for example ultrasound welding of the case or thin

PCB’s in watches) please fix the sensor with drops of low stress epoxy (for example Hysol FP-4401).

MOUNTING

The MS5540C can be placed with automatic Pick&Place equipment using vacuum nozzles. It will not be

damaged by the vacuum. Due to the low stress assembly the sensor does not show pressure hysteresis effects.

Special care has to be taken to not touch the protective gel of the sensor during the assembly.

It is important to solder all contact pads. The Pins PEN and PV shall be left open or connected to VDD. Do not

connect the Pins PEN and PV to GND!

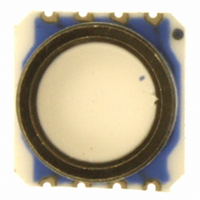

SEALING WITH O-RING

In products like outdoor watches the electronics must be protected against direct water or humidity. For those

products the MS5540C provides the possibility to seal with an O-ring. The protective cap of the MS5540C is

made of special anticorrosive and antimagnetic stainless steel with a polished surface. In addition to this the

MS5540C is filled with silicone gel covering the sensor and the bonding wires. The O-ring (or O-rings) shall be

placed at the outer diameter of the metal cap. This method avoids mechanical stress because the sensor can

move in vertical direction.

CLEANING

The MS5540C has been manufactured under cleanroom conditions. Each device has been inspected for the

homogeneity and the cleanness of the silicone gel. It is therefore recommended to assemble the sensor under

class 10’000 or better conditions. Should this not be possible, it is recommended to protect the sensor opening

during assembly from entering particles and dust. To avoid cleaning of the PCB, solder paste of type “no-clean”

shall be used. Cleaning might damage the sensor!

ESD PRECAUTIONS

The electrical contact pads are protected against ESD up to 4 kV HBM (human body model). It is therefore

essential to ground machines and personal properly during assembly and handling of the device. The MS5540C

is shipped in antistatic transport boxes. Any test adapters or production transport boxes used during the

assembly of the sensor shall be of an equivalent antistatic material.

DA5540C_001

February 20th, 2008

17

0005540C1193 ECN 1037