MS5535-CM Measurement Specialties Inc., MS5535-CM Datasheet - Page 15

MS5535-CM

Manufacturer Part Number

MS5535-CM

Description

SENSOR PRESURE 14 BAR 16BIT

Manufacturer

Measurement Specialties Inc.

Datasheet

1.MS5535-CM.pdf

(21 pages)

Specifications of MS5535-CM

Pressure Type

Absolute

Operating Pressure

203.05 PSI, 14bar

Output

Digital

Voltage - Supply

2.2 V ~ 3.6 V

Termination Style

PCB

Operating Temperature

-40°C ~ 125°C

Package / Case

9 x 9mm Module

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

223-1101-2

APPLICATION INFORMATION

GENERAL

The advantage of combining a pressure sensor with a directly adapted integrated circuit is to save other external

components and to achieve very low power consumption. The main application field for this system includes

portable devices with battery supply, but its high accuracy and resolution make it also suited for industrial and

automotive applications. The possibility to compensate the sensor with software allows the user to adapt it to his

particular application. Communication between the MS5535C and the widely available microcontrollers is realised

over an easy-to-use 3-wire serial interface. Customers may select which microcontroller system to be used, and

there are no specific standard interface cells required, which may be of interest for specially designed 4 Bit-

microcontroller applications.

CALIBRATION

The MS5535C is factory calibrated. The calibration data is stored inside the 64-Bit PROM memory.

SOLDERING

Please refer to the application note AN808 for all soldering issues.

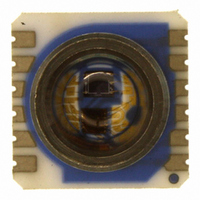

HUMIDITY, WATER PROTECTION

The MS5535CM carries a metal protection cap filled with silicone gel for enhanced protection against humidity.

The properties of this gel ensure function of the sensor even when in direct water contact. This feature can be

useful for waterproof watches or other applications, where direct water contact cannot be avoided. Nevertheless

the user should avoid drying of hard materials like for example salt particles on the silicone gel surface. In this

case it is better to rinse with clean water afterwards. Special care has to be taken to not mechanically damage

the gel. Damaged gel could lead to air entrapment and consequently to unstable sensor signal, especially if the

damage is close to the sensor surface.

The metal protection cap is fabricated of special anticorrosive stainless steel in order to avoid any corrosive

battery effects inside the final product.

LIGHT SENSITIVITY

The MS5535C is sensitive to sunlight, especially to infrared light sources. This is due to the strong photo effect

of silicon. As the effect is reversible there will be no damage, but the user has to take care that in the final

product the sensor cannot be exposed to direct light during operation. This can be achieved for instance by

placing mechanical parts with holes in such that light cannot pass.

CONNECTION TO PCB

The package outline of the module allows the use of a flexible PCB to connect it. This can be important for

applications in watches and other special devices, and will also reduce mechanical stress on the device.

For applications subjected to mechanical shock, it is recommended to enhance the mechanical reliability of the

solder junctions by covering the rim or the corners of MS5535C's ceramic substrate with glue or Globtop like

material.

DA5535C_003.doc

June 16th, 2008

15

000055351195 ECN1118