B32-1080 Omron, B32-1080 Datasheet - Page 7

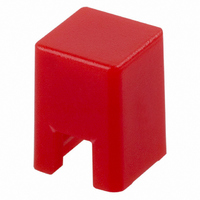

B32-1080

Manufacturer Part Number

B32-1080

Description

KEYCAP 4MM SQ RED FITS 6MM SER

Manufacturer

Omron

Series

B32r

Type

Key Cap for Mechanical Key Switchesr

Specifications of B32-1080

Features

Dustproof construction ensures highly reliable performance at low voltage and very small

Switch Type

Tactile

Shape

Square

Color

Red

Illumination

Non-Illuminated

Mounting Type

Slip On

Size

4.00mm L x 4.00mm W x 5.50mm H

Application

Key to Top Designed Specially

Height

4 mm

Illumination Color

Red

Length

4 mm

Width

2.5 mm

Thread Size

6 mm x 6 mm

Actuator / Cap Color

Red

Length/height, External

5.5mm

External Width

4mm

Knob / Dial Style

Square

External Height

4mm

Mounting Style

Panel

Standards

RoHS Compliant

For Use With

SW792 - SWITCH TACT 6MM 150GF SPST SMDSW791 - SWITCH TACT 6MM 100GF SPST SMDB3F-6152 - SWITCH TACT 6MM 150GF H=7.3MM (B3F-6150 - SWITCH TACT 6MM 100GF H=7.3MM (SW799 - SWITCH TACT 6MM 150GF H=7.3MMSW798 - SWITCH TACT 6MM 100GF H=7.3MMSW1052 - SWITCH TACT 6MM 260GF H=6.15MMSW850 - SWITCH TACT 6.5MM 150GF H-7.3MMSW795 - SWITCH TACT 6MM 260GF H=7.3MMSW964 - SWITCH TACT 6MM 100GF H=7.3MMSW405 - SWITCH TACT 6MM MOM 150GFSW420 - SWITCH TACT 6MM MOM 230GF SEALEDSW419 - SWITCH TACT 6MM MOM 160GF SEALEDSW410 - SWITCH TACT 6MM RT ANG 150GFSW409 - SWITCH TACT 6MM RT ANG 100GFSW404 - SWITCH TACT 6MM MOM 100GF

Lead Free Status / RoHS Status

Lead free / Not applicable

For Use With/related Products

B3F and B3W Series

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

B321080

SW252

SW252

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

B32-1080

Manufacturer:

OMRON

Quantity:

12 000

Precautions

Safety Precautions

■

Use the Switch within the rated voltage and current ranges, other-

wise the Switch may have a shortened life expectancy, radiate

heat, or burn out. This particularly applies to the instantaneous

voltages and currents when switching.

■

Storage

To prevent degradation, such as discoloration, in the terminals

during storage, do not store the Switch in locations that are sub-

ject to the following conditions.

Handling

1. Operation

Do not repeatedly operate the Switch with excessive force. Apply-

ing excessive pressure or applying additional force after the

plunger has stopped may deform the disc spring of the Switch,

resulting in malfunction. In particular, applying excessive force to

Side-operated Switches may damage the caulking, which in turn

may damage the Switch. Do not apply force exceeding the maxi-

mum (29.4 N for 1 minute, one time) when installing or operating

Side-operated Switches.

Be sure to set up the Switch so that the plunger will operate in a

straight vertical line. A decrease in the life of the Switch may

result if the plunger is pressed off-center or from an angle.

2. Dust Protection

Do not use Switches that are not sealed in dust-prone environ-

ments. Doing so may cause dust to penetrate inside the Switch

and cause faulty contact. If a Switch that is not sealed must be

used in this kind of environment, use a sheet or other measure to

protect it against dust.

PCBs

The Switch is designed for a 1.6-mm thick, single-side PCB.

Using PCBs with a different thickness or using double-sided,

through-hole PCBs may result in loose mounting, improper inser-

tion, or poor heat resistance in soldering. These effects will occur,

depending on the type of holes and patterns of the PCB. There-

fore, it is recommended that a verification test is conducted before

use.

If the PCBs are separated after mounting the Switch, particles

from the PCBs may enter the Switch. If PCB particles or foreign

particles from the surrounding environment, workbench, contain-

ers, or stacked PCBs become attached to the Switch, faulty con-

tact may result.

Soldering

1. General Precautions

Before soldering the Switch on a multilayer PCB, test to confirm

that soldering can be performed properly. Otherwise the Switch

may be deformed by the soldering heat on the pattern or lands of

the multilayer PCB.

1. High temperature or humidity

2. Corrosive gases

3. Direct sunlight

Precautions for Safe Use

Precautions for Correct Use

Incorrect Incorrect

Correct

Switch

Resin sheet

Plunger

Operating part

Do not solder the Switch more than twice, including rectification

soldering. An interval of five minutes is required between the first

and second soldering.

2. Automatic Soldering Baths (B3F, B3W, B3WN, B3M, B3J)

Soldering temperature: 260 ° C max.

Soldering time: 5 s max. for a 1.6-mm thick single-side PCB

Preheating temperature: 100°C max. (ambient temperature)

Preheating time: Within 60 s

Make sure that no flux will rise above the level of the PCB. If flux

overflows onto the mounting surface of the PCB, it may enter the

Switch and cause a malfunction.

3. Reflow Soldering (Surface Mounting)

Solder the terminals within the heating curve shown in the follow-

ing diagram.

B3S, B3SN, B3FS

Note:

The peak temperature may vary depending on the reflow bath

used. Confirm the conditions beforehand.

Do not use an automatic soldering bath for surface-mounted

Switches. The soldering gas or flux may enter the Switch and

damage the Switch’s push-button operation.

4. Manual Soldering (All Models)

Soldering temperature: 350 ° C max. at the tip of the soldering iron

Soldering time: 3 s max. for a 1.6-mm thick, single-side PCB

Before soldering the Switch on a PCB, make sure that there is no

unnecessary space between the Switch and the PCB.

Washing

1. Washable and Non-washable Models

Standard Switches are not sealed, and cannot be washed. Doing

so will cause the washing agent, together with flux or dust parti-

cles on the PCB, to enter the Switch, resulting in malfunction.

Washable (sealed types)

Non-washable (standard types) B3F, B3FS, B3M, B3J,

The above heating curve applies if the PCB thickness is

1.6 mm.

temperature

Max. 250

Room

220

180

150

Flux surface

PCB surface

60 to 120

Preheating

B3W, B3WN, B3S, B3SN

B3DA, B3D

Max. 60

Precautions

Time (s)

5