90B04ST Grayhill Inc, 90B04ST Datasheet - Page 2

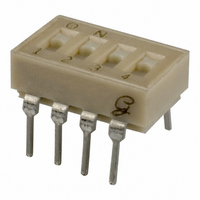

90B04ST

Manufacturer Part Number

90B04ST

Description

SWITCH DIP AUTO SEALED 4POS

Manufacturer

Grayhill Inc

Series

90Br

Type

DIPr

Specifications of 90B04ST

Circuit

SPST

Number Of Positions

4

Contact Rating @ Voltage

0.15A @ 30VDC

Actuator Type

Standard

Actuator Level

Flush

Mounting Type

Through Hole

Orientation

Top Actuated

Washable

Yes

Contact Configuration

SPCO

No. Of Switch Positions

4

Actuator Style

Flush Slide

Pitch Spacing

2.54mm

Contact Current Dc Max

100mA

Peak Reflow Compatible (260 C)

Yes

Circuitry

SPST-CO

Mounting

Through Hole

Pole Throw Configuration

4PST

Terminal Type

PC Pins

Brand/series

90B Series

Contact Form

SPST

Current, Rating

100 mA

Dielectric Strength

500 V

Special Features

Machine Insertable MIDIP

Termination

Through Hole

Voltage, Rating

30 VDC

Contact Current Max

10mA

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

GH7220

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

90B04ST

Manufacturer:

GHY

Quantity:

2 594

Part Number:

90B04ST

Manufacturer:

GRAYHIL

Quantity:

20 000

Grayhill, Inc. • 561 Hillgrove Avenue • LaGrange, Illinois 60525-5997 • USA • Phone: 708-354-1040 • Fax: 708-354-2820 • www.grayhill.com

Mechanical Ratings

Vibration Resistance: per Method 204, Test

Condition B, 1 mS opening (10 mS allowed)

Mechanical Shock: per Method 213, Test

Condition A. 1 mS opening (10 mS allowed)

Thermal Shock Resistance: per specification;

no failures; passes contact resistance.

Terminal Strength: per specification

Thermal Aging: 1,000 hours at 85°C; no failures.

Environmental Ratings

Meets all requirements of MIL- S-83504.**

spec is listed in parentheses.

Moisture Resistance: per MIL-STD-202,

Method 106.

SpeCIFICATIOnS: Standard Styles

WAVe SOLDeRInG: 260°C maximum solder temperature for 5 seconds max.

** note: 100% matte tin terminal plating does not meet MIL-S-83504 for lead content.

Where Grayhill performance is superior, the MIL

Ratings

Mechanical Life: Operations per switch position

Make-and-break Current Rating: Operations

per switch position at these resistive loads

1 mA, 5 Vdc; 50 mA, 30 Vdc; or 150 mA, 30 Vdc:

10 mA, 30 Vdc; or 10 mA, 50 mVdc:

10 mA, 50 mVdc; or 25 mA, 24 Vdc; or 100 mA, 6 Vdc:

Contact Resistance: Initially:

After life, at 10 mA, 50 mVdc, open circuit:

Insulation Resistance:

Minimum, at 100 Vdc between adjacent closed

contacts and also across open switch contacts

Dielectric Strength: Minimum voltage (AC,

RMS) measured between adjacent closed

contacts and also across open switch contacts.

Current Carry Rating: Maximum rise of 20°C

Switch Capacitance: At 1 megahertz

Operating Temperature Range:

Storage Temperature Range:

Initially (Mohms):

After life (Mohms):

lnitially:

After life:

Reflow Soldering

profile:

(260°C

peak Temperature)

Recommended Soldering Conditions:

Soldering Information

Series 90 MIDIp and Series 76 recessed rocker

(76RSB style) sealed switches have been tested

to eIA Standard RS-448-2. Similar performance

can be expected from other sealed Series 76

and 78 DIp switches.

Solderability: per MIL-STD-202, Method 208

Resistance to Soldering Heat: 76RSB:

passes eIA Standard using two, four, and six

second soldering time. 90: per MIL-S-83504,

six second test.

Fluxing: per eIA RS-448-2 with flux touching

switch body.

Cleaning: 76, 78 and 90 series tape sealed

products: passes immersion test using water/

detergent. Acceptable solutions include 1-1-1

trichlorethane, freon, (TF, Te, or TMS), isopropyl

alcohol, detergent (140°F maximum). Terpene

acceptable for Series 90 only. Solutions which are

not recommended include acetone, methylene

chloride, freon TMC.

-40°C to + 85°C

-55°C to + 85°C

≤ 100 mΩ

≤ 30 mΩ

750 V

500 V

2,000

2,000

5,000

1,000

2 pF

5 A

76

—

—

-40°C to + 85°C

-55°C to + 85°C

Thru-Hole DIP Switches

≤ 100 mΩ

≤ 30 mΩ

750 V

500 V

2,000

2,000

5,000

1,000

2 pF

4 A

78

—

—

Materials and Finishes

Shorting Member (Ball): Brass, gold-plated

over nickel barrier.

Base Contacts: Copper alloy, gold-plated

over nickel barrier.

Terminals: Copper alloy, matte tin plated over

nickel barrier.

Non-Conductive Parts: Thermoplastic

(UL94V-O)

Potting Material: epoxy, 76,78 only.

Protective Cover: 76,78, only-polycarbonate.

Tape Seal:

76, 78:

90:

Tape Seal Integrity: passes gross leak test

using 125°C flourinert for 20 seconds minimum.

Reference MIL-STD-202, Method 112.

-40°C to + 85°C

-55°C to + 85°C

polyester film

polyimide film

≤ 100 mΩ

≤ 20 mΩ

500 V

2,000

2,000

2,000

5,000

1,000

500 V

90B

2 pF

3 A

—

DIp

14