D2SW-P01L3T Omron, D2SW-P01L3T Datasheet - Page 5

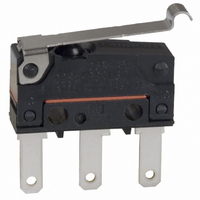

D2SW-P01L3T

Manufacturer Part Number

D2SW-P01L3T

Description

SWITCH SIM ROLL SPDT .1A .110QC

Manufacturer

Omron

Series

D2SW-Pr

Type

Basic/Snap Actionr

Specifications of D2SW-P01L3T

Circuit

SPDT

Switch Function

On-Mom

Contact Rating @ Voltage

0.1A @ 30VDC

Actuator Type

Lever, Simulated Roller

Mounting Type

Chassis Mount

Termination Style

Quick Connect - .110" (2.8mm)

Operating Force

61gf

Contact Form

SPDT

Contact Rating

0.1 Amp at 30 Volts

Actuator

Simulated Roller Lever

Ingress Protection

IP67, Watertight

Microswitch Type

Subminiature

Actuator Style

Simulated Roller Lever

Operating Force Max

0.6N

Contact Voltage Ac Nom

125V

Contact Voltage Dc Nom

30V

Contact Current Max

100mA

Body Style

Subminiature

Current, Rating

0.1 A

Dielectric Strength

1500 VAC

Force, Operating

1.8 N (Max.)

Ip Rating

IP67

Mounting Hole Size

M2.3

Number Of Poles

1

Operation

Snap Action

Standards

UL Recognized

Temperature Rating

-20 to +70 °C

Termination

Quick Connect

Voltage, Rating

30 VDC

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

D2SWP01L3T

SW805

Z2123

Z2123

SW805

Z2123

Z2123

Precautions

■ Cautions

Degree of Protection

Do not use this product in water. Although these models satisfy the

test conditions for the standard given below, this test is to check the

ingress of water into the switch enclosure after submerging the

Switch in water for a given time. Satisfying this test condition does

not mean that the Switch can be used in water.

IEC 60529: 2001 Degrees of protection provided by enclosures (IP

Code)

Code: IP67 (The test to meet the standard checks for water intrusion

after immersion for 30 minutes.)

Do not operate the Switch when it is exposed to water spray, or when

water drops adhere to the Switch surface, or during sudden tempera-

ture changes, otherwise water may intrude into the interior of the

Switch due to a suction effect.

Prevent the Switch from coming into contact with oil and chemicals.

Otherwise, damage to or deterioration of Switch materials may

result.

Do not use the Switch in areas where it is exposed to silicon adhe-

sives, oil, or grease, otherwise faulty contact may result due to the

generation of silicon oxide.

The environment-resistant performance of the switch differs depend-

ing on operating loads, ambient atmospheres, and installation condi-

tions, etc. Please perform an operating test of the switch in advance

under actual usage conditions.

Hinge Roller Lever Models

D2SW-P2L2@@

D2SW-P01L2@@

Simulated Roller Lever Models

D2SW-P2L3@@

D2SW-P01L3@@

t=0.3 Stainless-steel lever

t=0.3 Stainless-steel lever

2.35

2.35

+0.075

−0.05

2.5±

+0.075

-0.05

2.15

2.5±

0.07

7.3

3.2

2.15

dia.

0.07

7.3

3.2

dia.

5.15

5.15

8.55

19.8±

15.5

9.5±

8.55

19.8±

15.8±

15.5

9.5±

0.1

0.2

14.5±

0.6

0.1

0.2

0.6

A

A

Three, 1.6 dia. holes

R1.3

6.9

2.35

2.35

Three, 1.6 dia. holes

6.9

7.7

+0.075

−0.05

+0.075

-0.05

3.3±

7.7

OP

3.3±

0.1

dia. 4.8 x 3.2

Polyacetal resin roller

dia.

dia.

OP

FP

0.1

Sealed Subminiature Basic Switch

FP

Connecting to Terminals

Connecting to Solder Terminals

When soldering the lead wire to the terminal, first insert the lead wire

conductor through the terminal hole and the conduct soldering.

Make sure that the temperature at the tip of the soldering iron is 350

to 400°C. Do not take more than 3 seconds to solder the switch ter-

minal, and do not impose external force on the terminal for 1 min.

after soldering. Improper soldering involving an excessively high tem-

perature or excessive soldering time may deteriorate the characteris-

tics of the Switch.

Connecting to Quick-connect Terminals

Wire the quick-connect terminals (#110) with receptacles. Insert the

terminals straight into the receptacles. Do not impose excessive

force on the terminal in the horizontal direction, otherwise the termi-

nal may be deformed or the housing may be damaged.

Connecting to PCB Terminal Boards

When using automatic soldering baths, we recommend soldering at

260±5°C within 5 seconds. Make sure that the liquid surface of the

solder does not flow over the edge of the board.

When soldering by hand, as a guideline, solder with a soldering iron

with a tip temperature of 350 to 400°C within 3 seconds, and do not

apply any external force for at least 1 minute after soldering. When

applying solder, keep the solder away from the case of the Switch

and do not allow solder or flux to enter the case.

Side-actuated (Cam/Dog) Operation

When using a cam or dog to operate the Switch, factors such as the

operating speed, operating frequency, push-button indentation, and

material and shape of the cam or dog will affect the durability of the

Switch. Confirm performance specifications under actual operation

conditions before using the Switch in applications.

6.4±

0.5

6.4±

0.5

0.2

0.2

Model

OF max.

RF min.

OT min.

MD max.

FP max.

OP

Model

OF max.

RF min.

OT min.

MD max.

FP max.

OP

D2SW-P2L3@@

0.6 N {61 gf}

0.05 N {5 gf}

0.8 mm

0.8 mm

15.5 mm

10.7±0.8 mm

D2SW-P2L2@@

0.6 N {61 gf}

0.05 N {5 gf}

0.8 mm

0.8 mm

19.3 mm

14.5±0.8 mm

D2SW-P

D2SW-P01L3@@

D2SW-P01L2@@

5