169404 Tyco Electronics, 169404 Datasheet - Page 2

169404

Manufacturer Part Number

169404

Description

Crimping, Stripping, Cutting Tools & Drills CERTI-LOK DIE

Manufacturer

Tyco Electronics

Type

Crimping Dier

Datasheet

1.169404.pdf

(4 pages)

Specifications of 169404

Rohs Compliant

NA

Product

Tool Component

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

For Use With

Hand Crimp Tool 169400

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

three separate crimping closures that are color–coded

to match the color–coded terminal/splice for a given

wire range.

Note that Figure 1 indicates the number of dots that

will appear embossed on the crimped terminal or

splice. Observe the dot code on the finished crimp to

ensure that correct terminal/splice and die–closure

combination was used.

3. CRIMPING PROCEDURE

Determine your application requirements. Then, using

the table in Figure 1, make your selection according

to the following instructions:

Wire Size and Insulation Diameter – Make certain the

wire and insulation are within the specified range.

Wire Type and Strip Length – Using stranded wire,

strip it to the length shown. Do NOT crimp wire that

has cut or nicked strands.

Crimp terminal (or splice) as follows:

2

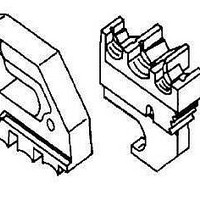

Crimping Dies 169404

of 4

C"

1. If necessary, install the dies according to the

instructions packaged with the tool.

C"

B"

B"

Typical PIDG and PLASTI-GRIP Terminals

PLASTI-GRIP

Terminal

Terminal

(Ring or Spade Receptacles)

PIDG

Figure 2

B" Equals Wire Barrel

C" Equals Insulation Barrel

C"

PIDG Insulating

Terminal Wire

Barrel Butts

Against Wire

Barrel Locator

Terminal Tongue

on Top of Locator

Restricting

B"

Tyco Electronics Corporation

First Crimp

2. Place terminal (or splice) in dies as shown in

Figure 2 or Figure 3.

3. Close tool handles until terminal or splice is held

firmly in place.

4. Insert properly stripped wire into terminal (or

splice) wire barrel “B” as shown in Figure 2 or

Figure 3.

5. Complete crimp by closing handles until ratchet

releases handles. Handles will open automatically

and crimped item may be removed.

6. To crimp other half of splice, remove it and

reposition uncrimped half in dies as shown in

Figure 3. Follow same procedure used to crimp

first half of splice. (If splice cannot be turned, turn

tool around.)

7. Inspect crimped terminal/splice. Check that

appropriate crimp code dot(s) appears on crimped

area of wire barrel. See Figure 1.

Conductor Butts

Against Splice

Wire Stop

Splice

Positioned

in Dies

B" Equals Wire Barrel

C" Equals Insulation Barrel

C"

PIDG Butt Splices

B"

Figure 3

Wire Stop

Window Indent

Conductor Butts

Against Splice

Wire Stop

Locator Seats in

Window Indent

of Splice

Second Crimp

408-6765

Rev

A