AZ8166 PANASONIC EW, AZ8166 Datasheet - Page 9

AZ8166

Manufacturer Part Number

AZ8166

Description

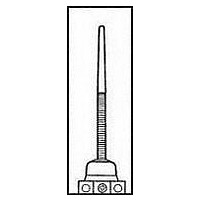

LIMIT SWITCH, FLEXIBLE ROD, SPDT

Manufacturer

PANASONIC EW

Datasheet

1.AZ8104.pdf

(24 pages)

Specifications of AZ8166

Actuator Style

Flexible Rod

Operating Force Max

0.88N

Contact Voltage Ac Max

250V

Contact Voltage Dc Max

125V

Contact Current Ac Max

5A

Contact Current Dc Max

400mA

Switch Terminals

Screw

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

WIRING

1. Insulation distance greater than

Reinforced plastic with superior electrical

insulation characteristics is used in the

wiring and charging sections. Despite its

compactness, to maintain stable insula-

tion performance, the insulation distance

for each part is greater than 6.4 mm

without using an insulation sheet.

(Complies with UL, CSA, and VDE.)

2. Includes ground terminal

3. Loose stop terminals used.

Applicable wire

CAUTIONS

1. Over travel (O.T.)

1) When overtravel is too large, life is

shortened due to possible damage to the

mechanism. Please use in the following

appropriate range.

2. Ambient conditions

1) Because these switches are not of

immersion protected construction, their

use in water or oil should be avoided.

Also, locations where water or oil can

normally impinge upon the switch or

where there is an excessive accumula-

tion of dust should be avoided.

2) The use of these switches under the

following conditions should be avoided. If

the following conditions should become

necessary, we recommend consulting us

first.

• Use where there will be direct contact

with organic solvents, strong acids or

alkalis, or direct exposure to their vapors.

Spring ( 4 locations )

Vinyl cabtire cord (VCTF)

Vinyl cabtire cable (VCT)

600V vinyl insulation sealed cable

(VVF)

(AZ8111, 8112, 8122)

(AZ8104, 8107, 8108)

6.4 mm

(AZ8166, 8169)

Projection ( 8 locations )

Flexible Rod

Roller Arm

Groove ( 8 points )

Plunger

Types

Wire name

(unit: mm inch)

.787inch

15 to 20mm

.059 to .079inch

1.5 to 2.0mm

Overtravel

20 to 30°

Terminal

washer

(at the top)

Terminal

screw

.591 to

Wire-strand

2-wire

3-wire

4-wire

2-wire

2-wire

Grounding terminal

• Use where inflammable or corrosive

gases exist.

3) Use within an ambient temperature of

–20 to +60°C

do not allow it to freeze.)

4) In order to maintain the reliability at a

high level under practical conditions of

use, the actual operating conditions

should be checked for the benefit of the

quality of the product.

5) If OT is too big, the life of limit switch

will be shortened switching friction. Use it

with enough margin of OT. 70% of OT

standard value will be good for use.

6) Do not use the switch in a silicon

atmosphere. Case should be taken

where organic silicon rubber, adhesive,

sealing material, oil, grease or lead wire

generates silicon.

7) When wiring, do not connect the lead

wires directly to the terminals, but use

the crimp terminals and tighten them to a

torque of 0.39 to 0.59 N·m {4 to 6

kg·cm}.

8) Avoid use in excessively dusty envi-

ronments where actuator operation

would be hindered.

1.0 dia. to 1.2 dia.

0.75mm

2.0mm

0.75mm

Applicable wire

Conductor

0.75mm

1.6 dia.

2

2

2

·1.25mm

·1.25mm

–4 to

2

2

2

+140°F. (However,

Finished outside diameter

Round shape

6 dia. to 9 dia.

Flat shape Max. 9.4

Applicable fasten terminal

With insulated grip

Max. 14

Max. 10

Max. 6.4

.551

Max. 6.4

.394

.252

.252

3.0 to 3.7 dia.

.118 to .146

3.0 to 3.7 dia.

.118 to .146

Max. 14

Max. 10

Max. 6.4

Max. 6.4

.551

.394

Head block direction

change

(Roller arm, adjustable roller arm, adjustable rod types)

Actuator heads

may be moved

in 90° incre-

ments to any of

four directions,

by removing

one screw.

9) When used outdoors (in places where

there is exposure to direct sunlight or

rain such as in multistory car parks) or in

environments where ozone is generated,

the influence of these environments may

cause deterioration of the rubber materi-

al. Please consult us if you intend to use

a switch in environments such as these.

10) Do not store in places where organic

gas might be generated or in places of

high dust content or high humidity.

3. Installation

1) Tighten the three cover installation

screws equally. Tightening torque is 0.2

to 0.29 N·m (2 to 3 kg·cm).

2) Avoid having extra cord length pushed

into the cord vent. Any extra length when

wiring should be allowed to rest in its

natural position.

.252

.252

3.0 to 3.7 dia.

.118 to .146

3.0 to 3.7 dia.

.118 to .146

Max. 10

Max. 6.4

Max. 6.4

.394

.252

3.0 to 3.7 dia.

.118 to .146

.252

3.0 to 3.7 dia.

.118 to .146

VL (AZ8)

16

Fasten terminal

.630

N.C. use

Lock screw ( Black )

32

1.260

N.O. use

59