LTL-10223W Lite-On Electronics, LTL-10223W Datasheet - Page 5

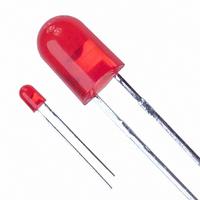

LTL-10223W

Manufacturer Part Number

LTL-10223W

Description

LAMP

Manufacturer

Lite-On Electronics

Type

Uni-Colorr

Specifications of LTL-10223W

Viewing Angle

60°

Package / Case

Radial - 2 Lead

Color

Red

Millicandela Rating

60mcd

Current - Test

10mA

Wavelength - Dominant

623nm

Wavelength - Peak

635nm

Voltage - Forward (vf) Typ

2V

Lens Type

Diffused, Red Tinted

Lens Style/size

Round, 5mm, T-1 3/4

Height

7.20mm

Mounting Type

Through Hole

Resistance Tolerance

623nm

Led Size

T-1 3/4

Illumination Color

High Efficiency Red

Lens Color/style

Diffused

Operating Voltage

2 V

Wavelength

625 nm

Luminous Intensity

60 mcd

Operating Current

20 mA

Lens Dimensions

5 mm

Lens Shape

Dome

Maximum Operating Temperature

+ 100 C

Minimum Operating Temperature

- 55 C

Mounting Style

Through Hole

Package Type

T-1 3/4

Emitting Color

Red

Test Current (it)

10mA

Forward Current

30mA

Dominant Wave Length

623nm

Forward Voltage

2.6V

Product Length (mm)

4.75mm

Product Height (mm)

7.2mm

Product Depth (mm)

4.75mm

Mounting

Through Hole

Peak Wavelength

635nm

Shape Type

Circular

Main Category

Standard LED

Number Of Elements

1

Pin Count

2

Operating Temperature Classification

Industrial

Operating Temp Range

-55C to 100C

Reverse Voltage

5V

Power Dissipation

100mW

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Luminous Flux @ Current - Test

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

160-1087

LT1087

LT1087

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

LTL-10223W

Manufacturer:

LITEON

Quantity:

40 000

Company:

Part Number:

LTL-10223W

Manufacturer:

Lite-On Inc

Quantity:

44 201

Company:

Part Number:

LTL-10223W-132A

Manufacturer:

LITEON

Quantity:

40 000

Company:

Part Number:

LTL-10223WH91

Manufacturer:

LITEON

Quantity:

40 000

Company:

Part Number:

LTL-10223WP

Manufacturer:

LITEON

Quantity:

40 000

1. Application

2. Storage

3. Cleaning

4. Lead Forming & Assembly

5. Soldering

Part No. : LTL-10223W

BNS-OD-C131/A4

During lead forming, the leads should be bent at a point at least 3mm from the base of LED lens.

Do not use the base of the leadframe as a fulcrum during forming.

Lead forming must be done before soldering, at normal temperature.

During assembly on PCB, use minimum clinch force possible to avoid excessive mechanical stress.

When soldering, leave a minimum of 2mm clearance from the base of the lens to the soldering point.

The storage ambient for the LEDs should not exceed 30°C temperature or 70% relative humidity.

It is recommended that LEDs out of their original packaging are used within three months.

For extended storage out of their original packaging, it is recommended that the LEDs be stored in

a sealed container with appropriate desiccant or in desiccators with nitrogen ambient.

Use alcohol-based cleaning solvents such as isopropyl alcohol to clean the LEDs if necessary.

Dipping the lens into the solder must be avoided.

Do not apply any external stress to the lead frame during soldering while the LED is at high temperature.

The LEDs described here are intended to be used for ordinary electronic equipment (such as office

equipment,

advance for information on applications in which exceptional reliability is required, particularly when

the failure or malfunction of the LEDs may directly jeopardize life or health (such as in aviation,

transportation, traffic control equipment, medical and life support systems and safety devices).

Note: Excessive soldering temperature and/or time might result in deformation of the LED lens or

Recommended soldering conditions :

Temperature

Soldering time

catastrophic failure of the LED. IR reflow is not suitable process for through hole type LED lamp

product.

Soldering iron

communication equipment and household applications).Consult Liteon’s Sales in

300°C Max.

3 sec. Max.

(one time only)

LITE-ON TECHNOLOGY CORPORATION

P r o p e r t y o f L i t e - O n O n l y

CAUTIONS

Pre-heat

Pre-heat time

Solder wave

Soldering time

Wave soldering

100°C Max.

60 sec. Max.

260°C Max.

10 sec. Max.

Page : 5

of

7