E-S-F EVERETT CHARLES TECH, E-S-F Datasheet - Page 2

E-S-F

Manufacturer Part Number

E-S-F

Description

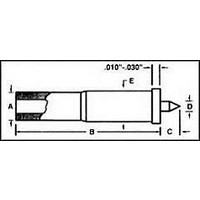

TEST SPRING PROBE, PCB, SOLDER

Manufacturer

EVERETT CHARLES TECH

Datasheet

1.A-A-S-R.pdf

(20 pages)

Specifications of E-S-F

Connector Type

Test Point

Current Rating

5A

Spring Force Initial

1oz

Spring Force Working Travel

3oz

Body Material

Brass

Tip / Nozzle Style

Flat

Spring Material

Beryllium Copper

Contact Material

Beryllium Copper

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

The Pylon Pogo

design features that enable our Pogo Contacts to achieve

the lowest, most consistent contact resistance available in

the marketplace.

The figure above depicts the biasing angle (ø), spring force (F), radial or side

force (F 1 ) and plunger force (F 2 ) of Biasing-Ball Pogo Contacts.

Contact Resistance

In evaluating contact resistance, low levels of resistance

are important. However, the more critical performance

measurement is the consistency of the low contact resistance.

Resistance measured as 8 milliohms at 1000 cycles must

The Pylon

F

1

100

ø

80

60

40

20

0

®

Contact advantage comes in two unique

100

®

Advantage

200

300

F

400

CYCLES (x 1,000)

500

F

2

600

These features are:

• The biasing ball construction of the Pogo Plunger

• Gold lined nickel silver tubing material for the Pogo

Pylon’s Biasing Ball Plungers

Biasing-Ball Construction* creates a radial component force

insuring a positive and uniform electrical junction between

the contact plunger and gold-alloy lining of the contact body.

also measure 8 milliohms at 200K, 500K and 1,000,000

cycles. The Biasing Ball design ensures that our Pogo

Contacts achieve consistent, low contact resistance. The

graph below plots the resistance of our P2663 Pogo series.

Note the consistency even to 3 sigma.

body on selected series

700

800

900

1,000

_

x +3s

_

x _

x -3s