210-93-314-41-001000 Mill-Max Manufacturing Corp., 210-93-314-41-001000 Datasheet

210-93-314-41-001000

Manufacturer Part Number

210-93-314-41-001000

Description

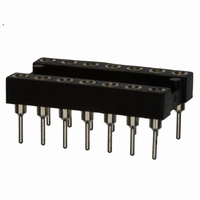

IC SOCKET 14DIP .300 TIN

Manufacturer

Mill-Max Manufacturing Corp.

Series

210r

Type

DIP, 0.3" (7.62mm) Row Spacingr

Datasheets

1.210-43-308-41-001000.pdf

(1 pages)

2.210-43-308-41-001000.pdf

(1 pages)

3.210-93-314-41-001000.pdf

(2 pages)

Specifications of 210-93-314-41-001000

Pitch

0.100" (2.54mm)

Features

Closed Frame

Number Of Positions Or Pins (grid)

14 (2 x 7)

Mounting Type

Through Hole

Contact Finish

Gold

Contact Finish Thickness

30µin (0.76µm)

Product

DIP / SIP Sockets

Number Of Rows

2

Number Of Positions / Contacts

14

Contact Plating

Gold over Nickel

Mounting Style

Through Hole

Termination Style

Solder Tail

Socket / Case Type

Closed Frame

Operating Temperature Range

- 55 C to + 125 C

Contact Material

Beryllium Copper

Contact Type

Type D

Insulation Resistance

10000 MOhms

Length

17.78 mm

Row Spacing

7.62 mm

Width

10.16 mm

Rohs Compliant

NO

Angle

Straight

Brand/series

210 Series

Current Rating

3 A

Current, Rating

3 A

Flammability Rating

UL 94V-0

Frame Type

Closed

Material, Body

Valox® PBT Polyester

Material, Contact

Beryllium Copper Alloy

Number Of Contacts

14

Number Of Positions

14

Pin Spacing

0.1 "

Primary Type

DIP

Spacing, Row To Row

0.3 in.

Termination

Thru-Hole

Voltage, Rating

100/150 Vrms/VDC

Peak Reflow Compatible (260 C)

No

No. Of Contacts

14

Pitch Spacing

2.54mm

Row Pitch

7.62mm

Contact Termination

Through Hole Vertical

Leaded Process Compatible

No

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Contains lead / RoHS non-compliant

Other names

2109331441001000

ED60001

ED60001

Mill-Max Mfg. Corp. Datasheet — Last Modified 10/10/2011

Product Number: 210-93-314-41-001000

CONTACT:

LOOSE PIN:

Contact Used: #30, Standard 4 Finger Contact

Current Rating = 3 Amps

BERYLLIUM COPPER ALLOY

ASTM B 194

Properties of BERYLLIUM COPPER:

Pin Used: 1001 (Brass Alloy)

Pins

Chemical composition: Cu 98.1%, Be 1.9%

Temper as stamped: TD01

Properties after heat treatment (TH01):

Hardness: 36-43 Rockwell C

Mechanical Life: 100 Cycles Min.

Density: .298 lbs/in3

Electrical Conductivity: 22% IACS*

Resistance: 10 miliohms Max

Operating Temperature: -55°C/+125°C

Melting point: 980°C/865°C (liquidus/solidus)

Stress Relaxation†: 96% of stress remains after

1,000 hours @ 100 °C ; 70% of stress remains

after 1,000 hours @ 200 °C

*International Annealed Copper Standard, i.e. as a % of pure copper.

†Since BeCu loses its spring properties over time at high temperatures; it is rated for continuous use up to 150°C. For

applications up to 300°C, Mill-Max offers many contacts in Beryllium Nickel. Contact Tech Support for more info.

Of

14

#

0.7

A

0.3

B

172 (UNS C17200) per

0.4

C

Tube

Qty.

per

28

210-93-314-41-001000

Mill-Max

Number

Part

Description:

DIP Socket

Solder Tail

Standard Solder Tail (0.125 Tail)

Closed Frame

Through Hole

Accepts .015-.025" Leads

Plating Code:

93

Shell Plating:

200 μ" Tin/Lead(93/7) over 100 μ"

Nickel

Inner Contact Plating:

30 μ" Gold over 50 μ" Nickel

Packaging:

Packaged in Tubes

Compliant

RoHS

Page 1 of 2

Related parts for 210-93-314-41-001000

210-93-314-41-001000 Summary of contents

Page 1

... Pin Used: 1001 (Brass Alloy) Mill-Max Mfg. Corp. Datasheet — Last Modified 10/10/2011 Qty. Mill-Max per Part Tube Number 28 210-93-314-41-001000 Description: DIP Socket Solder Tail Standard Solder Tail (0.125 Tail) Closed Frame Through Hole Accepts .015-.025" Leads Plating Code: 93 Shell ...

Page 2

BRASS ALLOY (UNS C36000) per ASTM B 16 Properties of BRASS ALLOY: Chemical composition: Cu 61.5%, Zn 35.4%, Pb 3.1%† Hardness as machined: 80-90 Rockwell B Density: .307 lbs/in3 Electrical conductivity: 26% IACS* Melting point: 900°C/885°C (liquidus/solidus) †( lead is used to ...