123-43-422-41-001000 Mill-Max Manufacturing Corp., 123-43-422-41-001000 Datasheet

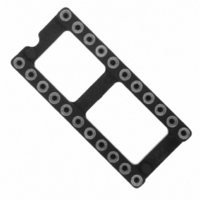

123-43-422-41-001000

Specifications of 123-43-422-41-001000

ED90173

Related parts for 123-43-422-41-001000

123-43-422-41-001000 Summary of contents

Page 1

... Pin Used: 0088 (Brass Alloy) Mill-Max Mfg. Corp. Datasheet — Last Modified 4/1/2011 L Qty. Mill-Max per Tube Number 0.510 18 123-43-422-41-001000 Description: DIP Socket Wrapost Tail 3 Level Wrapost Tail Open Frame Accepts .015-.025" Leads Plating Code: 43 Shell Plating: 200 μ" Tin (matte finish) over 100 μ ...

Page 2

BRASS ALLOY (UNS C36000) per ASTM B 16 Properties of BRASS ALLOY: Chemical composition: Cu 61.5%, Zn 35.4%, Pb 3.1%† Hardness as machined: 80-90 Rockwell B Density: .307 lbs/in3 Electrical conductivity: 26% IACS* Melting point: 900°C/885°C (liquidus/solidus) †( lead is used to ...

Page 3

Compliance Statement for Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) Reference: 1. Regulation EC No 1907/2006 of the European Parliament and of the Council of 18 December 2006, concerning the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) 2. ECHA, Candidate list of Substances of Very High Concern (SVHC) ...