DP-100 CLEAR 1.7 FL OZ 3M, DP-100 CLEAR 1.7 FL OZ Datasheet - Page 2

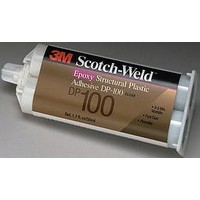

DP-100 CLEAR 1.7 FL OZ

Manufacturer Part Number

DP-100 CLEAR 1.7 FL OZ

Description

EPOXY 2 PART ADH DUAL CART 1.7FL.OZ

Manufacturer

3M

Series

Scotch-Weldr

Datasheet

1.DP-100_CLEAR_1.7_FL_OZ.pdf

(8 pages)

Specifications of DP-100 CLEAR 1.7 FL OZ

Adhesive Type

Epoxy - 2 Part

Adhesive Applications

Bonding - General Purpose

Color

Translucent

Dispensing Method

Dual Cartridge

Volume

1.7fl.oz. (US)

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

3M

Epoxy Adhesives

DP-100 Clear • DP-100 NS Translucent

Typical Cured

Properties

™

Scotch-Weld

Note: The following technical information and data should be considered representative

10. Thermal conductivity determined using ASTM C177 and C-matic Instrument with 2 in. diameter samples.

11. Color may vary from nearly white to yellow/amber. Adhesive performance is not affected by color variation.

5. Handling strength determined per 3M test method C-3179. Time to handling strength is the time required to achieve 50 psi

6. The cure time is defined as the time required for the adhesive to achieve a minimum of 80% of its ultimate OLS on aluminum.

7. Weight loss by Thermal Gravimetric Analysis reported as that temperature at which 5% weight loss occurs by TGA in air at 5°C

8. Glass transition temperature (Tg) determined using Perkin Elmer (DSC) Analyzer with a heating rate of 20°C (68°F) per minute.

9. Coefficient of thermal expansion determined using DuPont (TMA) using a heating rate of 10°C (50°F) per minute. Second heat

Product

Physical:

Color

Shore D Hardness

(ASTM D 2240)

Time to Handling Strength

Cure Time

Thermal:

Wt. loss by Thermal

Gravimetric Analysis

Glass Transition Temp

Coefficient of Thermal

Expansion (in./in./°C)

Thermal Conductivity

(btu-ft./sq. ft.-hr. °F)

Electrical:

Dielectric Strength

(ASTM D 149)

Volume Resistivity

(ASTM D 257)

OLS strength to aluminum.

(41°F) rise per minute per ASTM 1131-86 Test Procedures.

Second heat values given.

values given.

™

or typical only and should not be used for specification purposes.

6

7

10

9

8

- 2 -

5

24-48 hours @ 23°C (73°F)

15-20 min. @ 23°C (73°F)

209 x 10

60 x 10

0.107 @ 46°C (115°F)

5% @ 307°C (585°F)

(+140°F to +248°F)

3.5 x 10

(-38°F to +68°F)

DP-100 Clear

Translucent

860 volts/mil

33°C (91°F)

-6

3M™ Scotch-Weld™ Epoxy Adhesive

-6

(-40°C to +20°C)

80-85

(60°C to 120°C)

12

ohm-cm

11

24-48 hours @ 23°C (73°F)

15-20 min. @ 23°C (73°F)

149 x 10

29 x 10

DP-100 NS Translucent

0.106 @ 45°C (113°F)

(+122°F to +230°F)

2.2 x 10

(-56°F to +86°F)

Translucent

1100 volts/mil

34°C (86°F)

-6

-6

(-50°C to +30°C)

80-85

(50°C to 110°C)

14

ohm-cm

11