DP-270 BLACK 1.7 FL OZ 3M, DP-270 BLACK 1.7 FL OZ Datasheet - Page 4

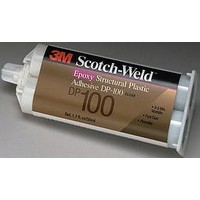

DP-270 BLACK 1.7 FL OZ

Manufacturer Part Number

DP-270 BLACK 1.7 FL OZ

Description

EPOXY 2 PART ADH CARTRIDGE 1.7FL.OZ

Manufacturer

3M

Series

Scotch Weldr

Datasheet

1.DP-270_BLACK_1.7_FL_OZ.pdf

(8 pages)

Specifications of DP-270 BLACK 1.7 FL OZ

Adhesive Type

Epoxy - 2 Part

Adhesive Applications

Potting / Bonding - Electronic Components

Color

Black

Dispensing Method

Dual-Cartridge

Volume

1.7fl.oz. (US)

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

3M

Epoxy Potting Compound/Adhesive

DP270 Clear and Black

Typical Cured

Properties (continued)

Typical Adhesive

Performance

Characteristics

™

Scotch-Weld

Note: The following technical information and data should be considered representative

Although 3M™ Scotch-Weld™ Epoxy Potting Compound/Adhesive DP270 and 270

B/A can be used for many potting and encapsulation applications, they can also be used

as adhesives. The following shows typical shear and peel values determined on several

common substrates:

Overlap Shear Adhesion (ASTM D-1002-72)

Note: The following technical information and data should be considered representative

90° T-Peel Adhesion (ASTM D-1876-61T)

Compression Strength (ASTM D-695-68T)

Corrosion:

Solvent Resistance:

Alum./Alum. (etched)

FR-4/FR-4 (MEK Wiped)

Copper/Copper (MEK Wiped)

Alum./Alum. (etched)

Scotch-Weld epoxy potting compound/adhesive

DP270 Clear and Black

™

Per ASTM D-3482

Per 3M Test Method C-708

Per Mil S-46163

(Visual check after immersion in specified solvent at 23°C (73°F)

Acetone

Isopropyl Alcohol

Freon TF

Freon TMC

1,1,1-Trichloroethane

RMA Flux

or typical only and should not be used for specification purposes.

or typical only and should not be used for specification purposes.

(35°C/95°F/96% R.H./45V d.c./15 days)

(45°C/113°F/96% R.H./250V d.c./5 days)

(65°C/149°F/96% R.H./250V d.c./4 days)

(10 days/50% R.H./23°C/73°F)

Key: A - Unaffected

B - Slight Attack

C - Moderate/Severe Attack

- 4 -

1 Hour

B

A

A

B

A

A

1 Month

@-67°F (-55°C)

@180°F (82°C)

Pass - No copper corrosion

Pass - No copper corrosion

Pass - No copper corrosion

Pass - No aluminum, brass or steel

discoloration or corrosion

@73°F (23°C)

@73°F (23°C)

@73°F (23°C)

@73°F (23°C)

@73°F (23°C)

C

B

A

C

C

B

7 days /73°F (23°C)

Curing Conditions

1200-1250 psi

2450-2500 psi

1750-1800 psi

1700-1750 psi

300-350 psi

8100 psi

< 2 piw