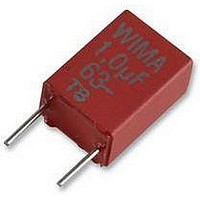

MKS2 0.22UF +/-10% 100V WIMA, MKS2 0.22UF +/-10% 100V Datasheet - Page 4

MKS2 0.22UF +/-10% 100V

Manufacturer Part Number

MKS2 0.22UF +/-10% 100V

Description

CAPACITOR, 0.22UF, 100V

Manufacturer

WIMA

Datasheet

1.MKS2C021001A00KSSD.pdf

(4 pages)

Specifications of MKS2 0.22UF +/-10% 100V

Capacitor Dielectric Type

Polyester

Capacitance

0.22µF

Capacitance Tolerance

± 10%

Voltage Rating

100VDC

Life Time @ Temperature

300000 Hours @ 40°C

Capacitor Case Style

Radial

No. Of Pins

2

Capacitor

RoHS Compliant

100

Designation

Carrier tape width

Hold-down tape width

Hole position

Hold-down tape position

Feed hole diameter

Pitch of component

Feed hole pitch

Feed hole centre

to lead

Hole centre to

component centre

Feed hole centre to bottom

edge of the component

Feed hole centre to top

edge of the component

Lead spacing at

upper edge of carrier tape

Lead diameter

Component alignment

Total tape thickness

Package

(see also page 101)

Unit

v

„

*

Please give „H“ dimensions and desired packaging type when ordering.

Diameter of leads see General Data.

PCM 10 and PCM 15 can be crimped to PCM 7.5.

Position of components according to PCM 7.5 (sketch 1). P

Typical Dimensions for

Taping Configuration

Diagram 2: PCM 10/15 mm

Symbol PCM 2.5 taping

W

W

W

H

Dh

W

D

H

P

P

P

d

P

F

v

t

0

1

2

0

1

v

0

1

2

REEL

18.0

6.0

9.0

0.5 to 3.0 max.

4.0

12.7

12.7

5.1

6.35

16.5

18.5

H+H

32.25 max.

2.5

0.4

p 2.0 max.

0.7

for hot-sealing

adhesive tape

p0.5

p0.2

p0.5

p0.5

p0.05

p0.2

component

p0.5

p1.0

p0.3

p1.3

p0.3

p0.5

P 360 max.

P 30 p1

F

cumulative pitch

1.0 mm/20 pitch

error max.

P

< H

1

ROLL/AMMO

1

P

P

1

2

B

PCM 5 taping

18.0

6.0

9.0

0.5 to 3.0 max.

4.0

12.7

12.7

3.85

6.35

16.5

18.5

H+H

32.25 max.

5.0

0.5

p 2.0 max.

0.7

P

P

F

0

52 p2

58 p2

for hot-sealing

adhesive tape

p0.5

p0.2

+0.8

p0.05

p0.2

–0.2

component

p0.5

p1.0

p0.3

p0.7

p1.3

p0.3

p0.5

d

P

P

0

P

0

2

depending on

comp. dimensions

= 12.7 or 15.0 is possible

cumulative pitch

1.0 mm/20 pitch

error max.

< H

d

1

D

0

PCM 7.5 taping

18.0

12.0

9.0

0.5 to 3.0 max.

4.0

12.7

12.7

2.6

6.35

16.5

18.5

H+H

24.5 to 31.5

7.5

„

p 3.0 max.

0.7

0.5

p0.5

p0.2

p0.7

p0.8

p0.2

component

p0.5

for hot-sealing

adhesive tape

p1.0

p0.3

p1.3

p0.5

p0.5

p0.05 or

Diagram 3: PCM 22.5 and 27.5*mm

*PCM 27.5 taping possible with two feed holes between components

cumulative pitch

1.0 mm/20 pitch

error max.

0.7

Dimensions for Radial Taping

< H

+0.07

–0.05

1

)h

REEL

PCM 10

18.0

12.0

9.0

0.5 to 3.0 max.

4.0

25.4

12.7

7.7

12.7

16.5

18.5

H+H

25.0 to 31.5

10.0

„

p 3.0 max.

0.7

see details page 103.

0.5

p0.5

p0.2

p0.7

p0.2

p0.5

for hot-sealing

p1.0

p0.3

p1.3

p0.5

p0.5

component

p0.8

p0.05 or

P 360 max.

P 30 p1

adhesive tape

F

taping*

cumulative pitch

1.0 mm/20 pitch

error max.

0.7

< H

Diagram 1:

PCM 2.5/5/7.5mm

+0.07

B 58 p2 or

–0.05

P

1

52 p2

66 p2

2

Please clarify customer-specific deviations with the manufacturer.

P

PCM 15

18.0

12.0

9.0

0.5 to 3.0 max.

4.0

25.4

12.7

5.2

12.7

16.5

18.5

H+H

26.0 to 37.0

15

0.8

p 3.0 max.

0.7

REEL

1

p0.8

+0.08

p0.5

p0.2

p0.7

–0.05

p0.2

P

component

p0.5

for hot-sealing

adhesive tape

p1.0

p0.3

p1.3

p0.5

p0.5

AMMO

P 500 max.

P 25 p1

d

taping*

cumulative pitch

1.0 mm/20 pitch

error max.

P

0

< H

1

B 60 p2

54 p2

68 p2

PCM 22.5 taping

18.0

12.0

9.0

0.5 to 3.0 max.

4.0

38.1

12.7

7.8

19.05

16.5

18.5

H+H

30.0 to 43.0

22.5

0.8

p 3.0 max.

0.7

+0.08

depending

on PCM and

component dimensions

p0.5

p0.2

p0.7

–0.05

p0.2

p0.5

for hot-sealing

p1.5

p0.3

p0.5

p0.5

component

p0.8

adhesive tape

p1.3

cumulative pitch

1.0 mm/20 pitch

error max.

< H

1

PCM 27.5 taping

18.0

12.0

9.0

0.5 to 3.0 max.

4.0

3 * 8.1

12.7

5.3

19.05

16.5

18.5

H+H

35.0 to 45.0

27.5

„

p 3.0 max.

0.7

0.8

p0.5

p0.2

p0.7

p0.2

p1.5

component

+0.08

p0.5

for hot-sealing

adhesive tape

p0.3

p0.5

p0.5

p0.8

–0.05 or

p1.3

Dims in mm.

or 50.8

cumulative pitch

1.0 mm/20 pitch

error max.

1.0

< H

D

+0.1

–0.05

p1.5

1