T521D107M016ATE050 Kemet, T521D107M016ATE050 Datasheet - Page 8

T521D107M016ATE050

Manufacturer Part Number

T521D107M016ATE050

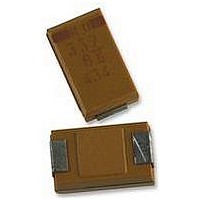

Description

CAPACITOR, V CASE, 100UF, 16V

Manufacturer

Kemet

Series

T521r

Type

Moldedr

Specifications of T521D107M016ATE050

Capacitance

100µF

Capacitance Tolerance

± 20%

Voltage Rating

16V

Esr

0.05ohm

Capacitor Case Style

D

No. Of Pins

2

Operating Temperature Range

-55°C To +105°C

Svhc

No SVHC (15-Dec-2010)

Package /

RoHS Compliant

Tolerance

20 %

Package / Case

2917 (7343-31 metric)

Dimensions

4.3 mm W x 7.3 mm L

Height

2.8 mm

Mfr Case Code

D Case

Product

Tantalum Organic Polymer Low ESR

Lead Spacing

3.8 mm

Termination Style

SMD/SMT

Voltage - Rated

16V

Esr (equivalent Series Resistance)

50.0 mOhm

Operating Temperature

-55°C ~ 105°C

Mounting Type

Surface Mount

Size / Dimension

0.287" L x 0.169" W (7.30mm x 4.30mm)

Height - Seated (max)

0.122" (3.10mm)

Manufacturer Size Code

D

Features

Polymer

Lifetime @ Temp.

-

Lead Free Status / Rohs Status

Details

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

T521D107M016ATE050

Manufacturer:

AVX

Quantity:

30 000

KEMET Organic Capacitor (KO-CAP) – T521 High Voltage Polymer Tantalum

Soldering Process

KEMET’s families of surface mount capacitors are compatible

with wave (single or dual), convection, IR or vapor phase reflow

techniques. Preheating of these components is recommended

to avoid extreme thermal stress. KEMET's recommended

profile conditions for convection and IR reflow reflect the profile

conditions of the IPC/J-STD-020D standard for moisture

sensitivity testing. The devices can safely withstand a maximum

of three reflow passes at these conditions.

Note that although the X/7343-43 case size can withstand wave

soldering, the tall profile (4.3 mm maximum) dictates care in wave

process development.

Hand soldering should be performed with care due to the difficulty

in process control. If performed, care should be taken to avoid

contact of the soldering iron to the molded case. The iron should

be used to heat the solder pad, applying solder between the pad

and the termination, until reflow occurs. Once reflow occurs, the

iron should be removed immediately. "Wiping" the edges of a chip

and heating the top surface is not recommended.

During typical reflow operations, a slight darkening of the gold-

colored epoxy may be observed. This slight darkening is normal

and is not harmful to the product. Marking permanency is not

affected by this change.

Construction

© KEMET Electronics Corporation • P.O. Box 5928 • Greenville, SC 29606 (864) 963-6300 • www.kemet.com

Silver Paint

Leadframe

(-Cathode)

Polymer /Ta

2

O

Carbon

5

/Ta

Tantalum Wire

Silver Adhesive

Weld

Note: All temperatures refer to the center of the package, measured on the

package body surface that is facing up during assembly reflow.

*Case Size D, E, P, Y and X

**Case Size A, B, C, H, I, K, M, R, S, T, U, V, W and Z

Time 25°C to Peak Temperature

Time within 5°C of Max Peak

Washer

Liquidous Temperature (T

Ramp-down Rate (T

Time (t

Time Above Liquidous (t

Temperature Max (T

Ramp-up Rate (T

Leadframe

(+Anode)

Profile Feature

Temperature Min (T

Peak Temperature (T

T

T

25

Preheat/Soak

smax

smin

Temperature (t

T

T

s

) from T

P

L

smin

L

to T

Max Ramp Up Rate = 3 ° C/sec

Max Ramp Down Rate = 6 ° C/sec

to T

P

P

)

Smin

Smax

to T

smax

P

P

)

)

)

)

L

)

L

)

L

)

)

SnPb Assembly

25° C to Peak

t

S

6 minutes max

3°C/sec max

6°C/sec max

60–150 sec

60–120 sec

20 sec max

235°C**

220°C*

100°C

150°C

183°C

Time

T2016_T521 • 9/6/2011

Pb-Free Assembly

t

L

8 minutes max

3°C/sec max

6°C/sec max

t

60–120 sec

60–150 sec

30 sec max

P

260°C**

250°C*

150°C

200°C

217°C

8 8