3-350566-1 Tyco Electronics, 3-350566-1 Datasheet - Page 37

3-350566-1

Manufacturer Part Number

3-350566-1

Description

MINI AMP-IN 22-18AWG PTLP/PHBZ

Manufacturer

Tyco Electronics

Series

Mini Amp-IN™r

Specifications of 3-350566-1

Contact Material

Phosphor Bronze

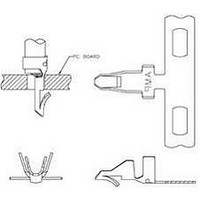

Terminal Type

Through Board, Locking

Hole Diameter

0.073" (1.85mm)

Insulation Diameter

0.060" ~ 0.110" (1.52mm ~ 2.79mm)

Length - Overall

0.250" (6.35mm)

Wire Gauge

18-22 AWG

Contact Finish

Tin

Connector Type

Contact, Crimp

Contact Plating

Tin

Peak Reflow Compatible (260 C)

No

Contact Termination

Crimp

Mounting Style

PCB

Termination Style

Crimp

Contact Gender

Male

Number Of Positions / Contacts

1

Product Type

Terminals

Wire Gauge Range

22-18

For Use With

0.062" Thickness PC Boards

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

3-350566-1

A100539TR

A100539TR

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

3-350566-1

Manufacturer:

TE/AMP

Quantity:

30 000

Company:

Part Number:

3-350566-1

Manufacturer:

TE

Quantity:

90 000

Company:

Part Number:

3-350566-1

Manufacturer:

TE

Quantity:

35 000

AMPOMATOR CLS IV+

Lead-Making Machines,

Part Nos. 356500-1, -2

AMP-O-LECTRIC Model “G”

Terminating Machines,

Part Nos. 354500-1, -9, -11

Catalog 82159

Revised 12-07

www.tycoelectronics.com

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

are metric equivalents.

Printed Circuit Board Terminals and Disconnects

Application Tooling

Fully-automatic machines

that measure, cut, strip and

terminate single leads.

Microprocessor-controlled,

and programmed and oper-

ated using an easy-to-follow,

menu-driven touch-screen.

Features include direct-

drive terminating units with

precision crimp height

adjustment, fully program-

mable setups, wire runout

and splice detection, and

motorized pre-feed with wire

straightener. Crimp quality

monitoring is also available.

For more information, request

Catalog 124324.

Semiautomatic bench

machines for crimping

reeled terminals and con-

tacts, featuring a quiet and

reliable direct motor drive,

microprocessor controls for

ease of setup and opera-

tion, and guarding and

lighting designed for opera-

tor convenience. All models

are equipped with either

manual or automatic preci-

sion adjustment of crimp

height. Machine-mounted

sensors are available for

crimp quality monitoring

using conventional minia-

ture-style applicators.

For more information, request

Catalog 65828.

Note: Part Numbers are RoHS compliant except:

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

AMP-O-MATIC Stripper-

Crimper Machines,

Part Nos. 1320895-1, -2

AMP 3K/40 and AMP 5K/40

Terminating Machines

Optional Stripping Module

for the AMP 3K/40,

AMP 5K/40 and

AMP-O-LECTRIC Model “G”

Terminating Machines

Indicates non-RoHS compliant.

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-1106-0803

Semiautomatic bench

crimping machines that also

strip the wire, and are there-

fore used for terminating

jacketed cable. Feature

manual precision adjust-

ment of crimp height, keyed

strip blades for faster, more

accurate setups, and an

efficient scrap removal sys-

tem. All adjustments can be

made from the front of the

machines without special

tools. Available with crimp

quality monitoring.

For more information, request

Catalog 65004.

As a value oriented termina-

tor, the AMP 3K/40 and

AMP 5K/40 terminators are

designed for customers that

require the increased output

and quality of a semiauto-

matic machine at a compet-

itive price. By incorporating

the most commonly

requested features as stan-

dard and offering a long list

of optional equipment, these

terminators offer flexibility to

meet the specific needs of

various applications at the

lowest possible cost.

For more information, request

Catalog 1654856.

The combination of the

Stripping Module with the

AMP-O-LECTRIC Model “G”

Terminator or the AMP 3K/40,

and AMP 5K/40 terminating

machines provides an eco-

nomical, proficient method

of stripping wire and crimp-

ing terminals on the same

machine. Wires are stripped

moments before crimping,

meaning there is virtually no

chance of damaging wire

conductors during handling

or storage. Once the wire is

fed into the start sensor, the

Stripping Module does the

rest, improving placement

accuracy.

For more information, request

Catalog 1309085.

South America: 55-11-2103-6000

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-8706-080-208

37