66570-3 TE Connectivity, 66570-3 Datasheet - Page 29

66570-3

Manufacturer Part Number

66570-3

Description

D SUB CONTACT, PIN, 18AWG, SOLDER

Manufacturer

TE Connectivity

Type

Contactr

Series

AMPLIMITE HDP-20r

Specifications of 66570-3

Number Of Contacts

1POS

Number Of Terminals

1

Plug / Receptacle

PIN

Contact Plating

Au over Pd Ni

Contact Pitch (mm)

Not Requiredmm

Body Orientation

Straight

Mounting Style

Cable

Number Of Ports

1Port

Number Of Contact Rows

Not Required

Operating Temp Range

-55C to 105C

Termination Method

Solder Cup

Current Rating

3.7A

Housing Material

Not Required

Contact Material

Brass

Operating Voltage (max)

250VAC

Product Length (mm)

14.86mm

Product Depth (mm)

2.15mm

Wire Size (awg)

18

Contact Termination

Solder

Contact Type

Signal

Accessory Type

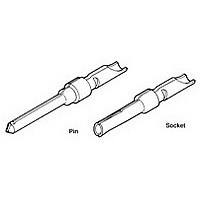

Pin & Socket Contact

Gender

Pin

Rohs Compliant

Yes

Contact Gender

Pin

Product Type

Contact

Product Series

HDP-20 (Crimp Snap)

Termination Method To Wire/cable

Solder

Insulation Support

No

Grade

Standard

Contact Retention In Housing

Crimp Snap-In

Solder Tail Contact Plating

Gold Flash over Nickel

Pin Diameter (mm [in])

1.02 [0.040]

Wire Range (mm² [awg])

0.8 - 0.9 [18]

Used With

CPC Connectors, AMPLIMITE HDP-20

Contact Base Material

Brass

Contact Plating, Mating Area, Material

Gold Flash over Palladium Nickel or Gold (30) over Nickel

Contact Size

20

Contact Configuration

Solder Cup

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Loose Piece

Lead Free Status / RoHS Status

Compliant

Crimp Quality Monitor (CQM)

This unique system pro-

vides 100% on-the-fly crimp

inspection. It measures the

crimp height of each termi-

nation, and evaluates the

quality of each crimp. If a

crimp is questionable, the

monitor alerts the operator

with both visual and audible

alarms. It also provides

ports for printing and net-

working. When used with

AMP-O-LECTRIC Model “G”

Termination Machines, the

monitor is mounted to the

machine. When used with

AMPOMATOR CLS IV Lead-

Making Machines, it is inte-

grated into the machine’s

operating system.

For complete information,

request Catalog 82275.

AMP-O-MATIC Stripper-

Crimper Machine

Semiautomatic bench

crimping machines that also

strip the wire, and are there-

fore used for terminating

jacketed cable. Feature

manual precision adjust-

ment of crimp height, keyed

strip blades for faster, more

accurate setups, and an

efficient scrap removal sys-

tem. All adjustments can be

made from the front of the

machines without special

tools. Available with crimp

quality monitoring.

For complete information,

request Catalog 65004.

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

are metric equivalents.

Precision Pin and Socket Contacts

Application Tooling

AMPOMATOR CLS IV+

Lead-Making Machine

Fully-automatic machines

that measure, cut, strip and

terminate single leads.

Microprocessor-controlled,

and programmed and oper-

ated using an easy-to-fol-

low, menu-driven touch-

screen. Features include

direct-drive terminating

units with precision crimp

height adjustment, fully pro-

grammable setups, wire

runout and splice detection,

and motorized pre-feed

with wire straightener.

Crimp quality monitoring is

also available.

For more information,

request Catalog 124324.

Quick-Change Applicators

These applicators can be

changed in minutes to

afford maximum flexibility

and minimum production

downtime for a wide range

of AMP automatic

machines. Crimp height for

a given wire size is simply

“dialed in.”

For complete information,

see specific AMP automatic

machine catalog.

Dimensions are shown for

reference purposes only.

Specifications subject to change.

Entry Level Terminator (ELT)

Semiautomatic bench termi-

nator for side- and end-feed

reeled terminals and con-

tacts. The ELT uses a DC

motor with gear box drive.

The result is a small-foot-

print design that is fast and

quiet. Cycle time is less

than 0.400 seconds with an

AMP-O-LECTRIC Model G Terminating Machine

Semiautomatic bench

machines for crimping

reeled terminals and con-

tacts, featuring a quiet and

reliable direct motor drive,

microprocessor controls for

ease of setup and opera-

tion, and guarding and

lighting designed for opera-

tor convenience. All models

are equipped with either

Technical Support

USA: 1-800-522-6752

Canada: 1-905-475-6222

Mexico: 01-800-733-8926

manual or automatic preci-

sion adjustment of crimp

height. Machine-mounted

sensors are available for

crimp quality monitoring

using conventional minia-

ture-style aplicators.

For complete information,

request Catalog 65828.

operation sound level of

76 dBA. It has a crimp

force capacity of 3,000

pounds. Optional equip-

ment is also available to

meet specific application

requirements.

For complete information,

request Catalog 1308382.

Central America: 52-55-5-729-0425

South America: 55-11-3611-1514

www.tycoelectronics.com

Catalog 65910

Revised 1-03

29