556881-6 TE Connectivity, 556881-6 Datasheet - Page 27

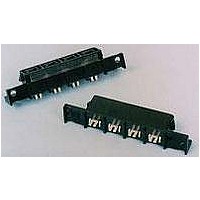

556881-6

Manufacturer Part Number

556881-6

Description

Power to the Board RCPT ASY VRT WTB 6 POS

Manufacturer

TE Connectivity

Type

Powerr

Datasheet

1.556881-6.pdf

(30 pages)

Specifications of 556881-6

Gender

F

Body Orientation

Straight

Number Of Contacts

6POS

Number Of Ports

1Port

Number Of Terminals

12

Contact Material

Copper Alloy

Voltage Rating Max

600VAC

Mounting Style

Through Hole

Termination Method

Solder

Contact Plating

Tin

Product Depth (mm)

14.43mm

Voltage Rating

600 V

Number Of Positions / Contacts

6

Termination Style

Solder

Product Type

Connector

Connector Type

Connector Assembly

Pcb Mounting Orientation

Vertical

Make First / Break Last

No

Pcb Mount Retention

Without

Termination Method To Pc Board

Through Hole - Solder

Pcb Mount Alignment

Without

Sealed

No

Ul File Number

E28476

Csa File Number

LR 7189

Mating Retention Type

Latching

Vde Tested

No

Contact - Rated Current (a)

35

Operating Voltage Reference

AC

Operating Voltage (vac)

600

Tail Length (mm [in])

4.9 [0.192]

Tail Orientation

In-line

Profile Height (y-axis) (mm [in])

12.70 [0.500]

Mating Retention

With

Number Of Positions

6

Centerline (mm [in])

11.18 [0.440]

Number Of Rows

1

Length (x-axis) (mm [in])

91.44 [3.600]

Width (z-axis) (mm [in])

19.30 [0.760]

Contact Base Material

Copper Alloy

Contact Type

Pin/Socket

Contact Design

Dual Beam

Contact Plating, Mating Area, Material

Tin

Contact Plating, Mating Area, Thickness (µm [?in])

3.81 [150]

Tail Plating Material

Tin

Tail Plating, Thickness (µm [?in])

2.54 [100]

Connector Style

Receptacle

Housing Material

Polyphenylene Sulfide

Housing Color

Black

Mating Alignment

With

Mating Alignment Type

Polarization

Ul Flammability Rating

UL 94V-0

Custom Configurable

No

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Agency/standard

UL, CSA

Ul Rating

Recognized

Ul Voltage Rating (vac)

600

Csa Certified

Yes

Operating Temperature (°c [°f])

0 – 105 [32 – 221]

Applies To

Printed Circuit Board

Pcb Thickness, Recommended (mm [in])

1.57 – 3.18 [0.062 – 0.1251]

Application Use

Wire-to-Board

Contact Transmits (typical Application)

Power

Packaging Method

Loose Piece

Lead Free Status / RoHS Status

Compliant

28

Catalog 1308885

Issued 3-05

www.tycoelectronics.com

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

are metric equivalents.

Power Connectors for

Industrial and Commercial Applications

Related Product Catalogs

Heavy Duty Seamless

Terminals and Splices

Catalog 1308674

The Heavy Duty Seamless

and Copper Compression

Lug and Splice line provides

a robust terminal line for

applications in the many

industries. The product is

used in applications includ-

ing industrial and welding

equipment, transportation/

marine cable harness, and

general-purpose harnesses.

The Heavy Duty Seamless

line utilizes deep-draw

stamping technology to cre-

ate a robust terminal without

butted seams along the wire

barrel or along the outer

edge of the ring tongue. The

Standard Terminals and

Splices Catalog 82042

AMP solderless terminals and

splices meet or exceed

today’s standards for reliable

termination in applications

ranging from control circuits

to heavy duty power wiring.

The catalog describes only

standard terminals and

splices accommodating wire

sizes from 26 AWG through

4/0 AWG

AMPOWER Terminals and

Splices Catalog 82025

The AMPOWER product line

is available in a variety of ter-

minal and splice styles to suit

your design requirements.

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

Heavy Duty Splice line offers

butt splice versions with

either flared or chamfered

wire barrels for ease of wire

entry and dimpled wire stops

to assist in proper wire place-

ment.

The Copper Compression

Lug and Splice line is a

formed tubular line for use on

cable assemblies in

Commercial equipment and

Industrial machinery. The

thicker tongue and wire bar-

rel of this line provide added

strength and rigidity for more

challenging applications.

The Battery Lug and Splice

line offers the thickest materi-

al and strength for your

industrial equipment and

The terminals are pre-insulat-

ed and color coded by wire

size for easy identification.

Funnel entry on many termi-

nals allows for easy wire

insertion for high speed pro-

duction

Nylon or vinyl insulation pro-

vides high dielectric strength

The serration or dimple fea-

ture inside the terminal barrel

provides maximum barrel

contact and tensile strength

AMPOWER terminals and

splices are ideally suited for

power generation and distri-

bution. This makes electrical

equipment subject to contin-

uous operation, such as gen-

erators, motors and welders,

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-5-729-0425

transportation harness appli-

cations.

Tyco Electronics has exten-

sive drawn sleeve capabili-

ties to help meet your cus-

tomized electrical sleeve

needs. The company manu-

factures specialized sleeves

used in general electrical

application and electrical

components. Tyco

Electronics has the capability

to manufacture sleeves in a

range of copper alloys and

has extensive post electro-

plating capabilities. Contact

us to review your application

and discuss the benefits we

can provide.

AMP’s special plating

process creates a high resist-

ance to corrosion

Use of AMP application tool-

ing is designed for uniform

high quality terminations

UL, CSA, Military Approved

a perfect application for

AMPOWER products. In

addition, other applications

include interconnections of

power supplies to computers

and peripheral equipment.

South America: 55-11-3611-1514

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-141-810-8967