31770 TE Connectivity, 31770 Datasheet - Page 50

31770

Manufacturer Part Number

31770

Description

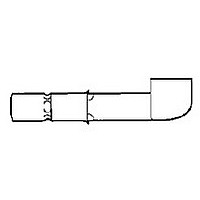

KNIFE DISCONNECT,DG 22-16

Manufacturer

TE Connectivity

Type

Splice Terminalr

Datasheet

1.31770.pdf

(60 pages)

Specifications of 31770

Wire Gauge

16-22

Body Plating

Tin

Body Material

Copper

Insulation

Non-Insulated

Product Depth (mm)

3.18mm

Color

Not Required

Rohs Compliant

YES

Product Type

Splice

Sealed

No

Splice Type

Knife Disconnect

Body Style

DIAMOND GRIP

Insulation Support

Insulation Support

Insulation Diameter (mm [in])

3.18 [.125] Max.

Finish

Tin

Wire/cable Size (cma)

509 – 3,260

Wire Range (mm [awg])

0.30-1.40² [22-16]

Government/industry Qualification

No

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Loose Piece

Lead Free Status / RoHS Status

Compliant

50

UL 486 C Wire Size

AWG 22 to 6

UL 486 A Wire Size

AWG 4 to 600 MCM

Test Sequences

Test Group 1

Mechanical Sequence

1. Secureness

2. Pullout

Test Group 2

Mechanical Sequence

1. Secureness

2. Static Heat

3. Pullout

Note: Testing conducted on non-plated

copper wire with UL approved insulation.

SOLISTRAND, Budget and DIAMOND GRIP

Uninsulated Terminals and Splices

Description of UL 486A & C Test Procedures and Requirements

for Butt and Parallel Type Splices

For drawings, technical data or samples, contact your AMP sales engineer or call the AMP Technical Support Center 1-800-522-6752.

Dimensions are in inches and millimeters unless otherwise specified. Values in brackets are metric equivalents.

Specifications subject to change. Consult AMP for latest specifications.

Pullout Test Requirements

Splices must not be separate from wire when

subjected to the listed load for one minute.

Wire Size

AWG

250

300

350

400

500

600

1/0

2/0

3/0

4/0

22

20

18

16

14

12

10

8

6

4

2

Force (lbs.)

Pullout

140

180

250

300

350

450

500

550

600

650

800

900

10

10

15

25

35

40

45

50

8

Secureness Test Requirements

Note: Test Duration=30 Minutes

Wire Size

18-16

12-10

AWG

14

8

6

4

Requirement:

Connector temperatures must not exceed the ambi-

ent temperature plus 50°C [90°F] after stability is

attained.

Stability:

A test sample is considered to have attained a stable

temperature when three readings taken at not less

than 10 minute intervals show no more than a 2°C

[3.6°F] variation between any two readings.

Static Heat Test Requirements

Wire Size

AWG

250

300

350

400

500

600

1/0

2/0

3/0

4/0

22

20

18

16

14

12

10

8

6

4

2

Bushing

Dia.

1/4

3/8

3/8

3/8

1/2

1/2

Height

10 1/4

11 3/4

11 3/4

11

11

11

Catalog 65505

Test Current

(Amperes)

Revised 9-00

125

170

230

265

310

360

405

445

505

545

620

690

12

17

18

30

35

50

70

95

Weight

9

(lbs.)

18

30

2

3

5

8