HSMS-2702-BLKG Avago Technologies US Inc., HSMS-2702-BLKG Datasheet - Page 8

HSMS-2702-BLKG

Manufacturer Part Number

HSMS-2702-BLKG

Description

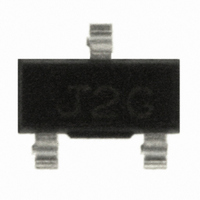

DIODE SCHOTTKY 15V 350MA SOT-23

Manufacturer

Avago Technologies US Inc.

Datasheet

1.HSMS-2702-BLKG.pdf

(9 pages)

Specifications of HSMS-2702-BLKG

Diode Type

Schottky - 1 Pair Series Connection

Voltage - Peak Reverse (max)

15V

Current - Max

350mA

Capacitance @ Vr, F

6.7pF @ 0V, 1MHz

Power Dissipation (max)

350mW

Package / Case

SOT-23-3, TO-236-3, Micro3™, SSD3, SST3

Capacitance Ct

6.7pF

Diode Case Style

SOT-23

Series Resistance @ If

0.65ohm

Peak Reflow Compatible (260 C)

Yes

Leaded Process Compatible

Yes

Forward Voltage

550mV

Breakdown Voltage

15V

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Resistance @ If, F

-

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

516-1911

HSMS-2702-BLKG

HSMS-2702-BLKG

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Part Number:

HSMS-2702-BLKG

Manufacturer:

AVAGO/安华高

Quantity:

20 000

Because the automatic, pick-and-place equipment used

to assemble these products selects dice from adjacent

sites on the wafer, the two diodes which go into the

HSMS-2702 or HSMS-270C (series pair) are closely

matched —without the added expense of testing and

binning.

Current Handling in Clipping/Clamping Circuits

The purpose of a clipping/clamping diode is to handle

high currents, protecting delicate circuits downstream

of the diode. Current handling capacity is determined

by two sets of characteristics, those of the chip or device

itself and those of the package into which it is mounted.

Figure 8. Two Schottky Diodes Are Used for Clipping/Clamping in a Circuit.

Consider the circuit shown in Figure 8, in which two

Schottky diodes are used to protect a circuit from noise

spikes on a stream of digital data. The ability of the diodes

to limit the voltage spikes is related to their ability to sink

the associated current spikes. The importance of current

handling capacity is shown in Figure 9, where the forward

voltage generated by a forward current is compared in

two diodes.

Figure 9. Comparison of Two Diodes.

The first is a conventional Schottky diode of the type

generally used in RF circuits, with an R

second is a Schottky diode of identical characteristics,

save the R

relatively high value of R

diode’s terminals to rise as current increases. The power

dissipated in the diode heats the junction, causing R

climb, giving rise to a runaway thermal condition. In the

second diode with low R

place and the voltage across the diode terminals is main-

8

noisy data-spikes

long cross-site cable

6

5

4

3

2

1

0

pull-down

(or pull-up)

0

S

I

F

of 1.0 Ω. For the conventional diode, the

– FORWARD CURRENT (mA)

0.1

current

limiting

0.2

R

R

s

s

0V

= 7.7

= 1.0

S

0.3

S

causes the voltage across the

voltage limited to

Vs + Vd

0V – Vd

, such heating does not take

Vs

0.4

0.5

S

of 7.7 Ω. The

S

to

tained at a low limit even at high values of current.

Maximum reliability is obtained in a Schottky diode when

the steady state junction temperature is maintained at or

below 150°C, although brief excursions to higher junction

temperatures can be tolerated with no significant impact

upon mean-time-to-failure, MTTF. In order to compute

the junction temperature, Equations (1) and (3) below

must be simultaneously solved.

where:

I

I

V

R

T

I

n = diode ideality factor

θ

lead)

T

Equation (1) describes the forward V-I curve of a Schottky

diode. Equation (2) provides the value for the diode’s satu-

ration current, which value is plugged into (1). Equation

(3) gives the value of junction temperature as a function

of power dissipated in the diode and ambient (lead)

temperature.

The key factors in these equations are: R

tance of the diode where heat is generated under high

current conditions; θ

the Schottky die; and θ

resistance.

R

and is the lowest of any Schottky diode available from

Avago. Chip thermal resistance is typically 40°C/W; the

thermal resistance of the iron-alloy-leadframe, SOT-23

package is typically 460°C/W; and the thermal resistance

of the copper-leadframe, SOT-323 package is typically

110°C/W. The impact of package thermal resistance on

the current handling capability of these diodes can be

seen in Figures 3 and 4. Here the computed values of

junction temperature vs. forward current are shown

S

O

F

J

S

A

S

F

JC

= saturation current

= forward current

= junction temperature

= saturation current at 25°C

= θ

= forward voltage

= series resistance

for the HSMS-270x family of diodes is typically 0.7 Ω

I

T

= ambient (diode lead) temperature

I

S

F

J

= thermal resistance from junction to case (diode

= I

= I

= V

package

0

S

F

I

F JC

e

298

11600 (V

T

+ θ

J

+ T

chip

2

n

A

nT J

e

F

–4060

– I

chip

F

R

, the chip thermal resistance of

package

S

–1

)

T

1

J

–

, or the package thermal

298

1

(1)

(2)

(3)

S

, the series resis-