5093NW1K000J08AFX Vishay, 5093NW1K000J08AFX Datasheet - Page 23

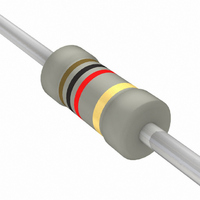

5093NW1K000J08AFX

Manufacturer Part Number

5093NW1K000J08AFX

Description

3W, 1K OHM, 5%

Manufacturer

Vishay

Series

PR03r

Datasheet

1.5093NW1R000J08AFX.pdf

(24 pages)

Specifications of 5093NW1K000J08AFX

Resistance (ohms)

1K

Power (watts)

3W

Composition

Metal Film

Features

Flame Retardant Coating

Temperature Coefficient

±250ppm/°C

Tolerance

±5%

Size / Dimension

0.205" Dia x 0.768" L (5.20mm x 19.50mm)

Lead Style

Through Hole

Package / Case

Axial

Resistance In Ohms

1.00K

Case

Axial

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Height

-

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

2322 195 13102

232219513102

BC1.0KW-3TB

232219513102

BC1.0KW-3TB

BCcomponents

TESTS AND REQUIREMENTS

Essentially all tests are carried out in accordance with the

schedule of “IEC publication 60115-1”, category

LCT/UCT/56 (rated temperature range: Lower Category

Temperature, Upper Category Temperature; damp heat,

long term, 56 days). The testing also covers the requirements

specified by EIA and EIAJ.

The tests are carried out in accordance with IEC publication

60068-2, “Recommended basic climatic and mechanical

robustness testing procedure for electronic components”

and under standard atmospheric conditions according to

“IEC 60068-1”, subclause 5.3.

Table 7

2001 Jul 13

Tests in accordance with the schedule of IEC publication 60115-1

4.4.1

4.4.2

4.5

4.18

4.29

4.17

4.7

60115-1

CLAUSE

Professional power metal film resistors

IEC

Test procedures and requirements

20 (Tb)

45 (Xa)

20 (Ta)

METHOD

60068-2

TEST

IEC

visual examination

dimensions (outline) gauge (mm)

resistance

resistance to

soldering heat

component solvent

resistance

solderability

voltage proof on

insulation

TEST

applied voltage (+0/ 10%):

thermal shock: 3 s; 350 C;

6 mm from body

isopropyl alcohol or H

followed by brushing

in accordance with “MIL 202 F”

2 s; 235 C

maximum voltage 500 V (RMS)

during 1 minute; metal block method

R

10

100

1 k

10 k

100 k

R = 1 M : 50 V

10

R

R

R

R

R

0.1 V

PROCEDURE

23

10 k : 3 V

100

100 k : 10 V

1 k : 1 V

1 M : 25 V

In Table 7 the tests and requirements are listed with

reference to the relevant clauses of

“IEC publications 60115-1 and 60068-2”; a short

description of the test procedure is also given. In some

instances deviations from the IEC recommendations were

necessary for our method of specifying.

All soldering tests are performed with mildly activated flux.

: 0.3 V

2

O

no holes; clean surface;

no damage

see Tables 4, 5 and 6

R

no visual damage

good tinning; no damage

no breakdown or flashover

R/R max.: 1% + 0.05

R

nom

REQUIREMENTS

: max. 5%

PR01/02/03

Product specification