104130-3 TE Connectivity, 104130-3 Datasheet - Page 274

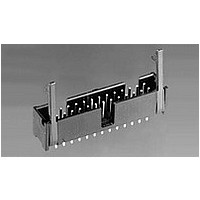

104130-3

Manufacturer Part Number

104130-3

Description

Conn Ejector Header HDR 16 POS 2.54mm Solder RA Thru-Hole

Manufacturer

TE Connectivity

Type

Ejector Headerr

Datasheet

1.1-102618-8.pdf

(320 pages)

Specifications of 104130-3

Pitch

2.54 mm

Number Of Rows

2

Number Of Contacts

16

Gender

HDR

Contact Plating

Gold Over Nickel

Termination Method

Solder

Product Line

AMP-LATCH

Profile

Low

Pcb Mounting Orientation

Right Angle

Pcb Mount Retention

Without

Mating Connector Lock

Without

Housing Style

4-Sided

Ejection Latches

With

Post Size (mm [in])

0.64 [.025]

Shrouded

Yes

[shrouded] End Dimension (mm [in])

3.81 [0.150]

Current Rating (a)

1

Insulation Resistance (m?)

5,000

Termination Post Length (mm [in])

3.43 [0.135]

Solder Tail Contact Plating

Tin-Lead over Nickel

Header Type

Pin Header

Number Of Positions

16

Centerline, Matrix (mm [in])

2.54 x 2.54 [.100 x .100]

Daisy Chain

With

Preloaded

Yes

Contact Plating, Mating Area, Material

Gold (30), Gold Flash over Palladium Nickel

Contact Shape

Square

Contact Base Material

Copper Alloy

Connector Style

Header - Pin

Mating Alignment Type

Center, Dual Polarizing Bar

Mating Alignment

With

Housing Material

Thermoplastic - GF

Ul Flammability Rating

UL 94V-0

Housing Color

Black

Rohs/elv Compliance

Not ELV/RoHS compliant

Lead Free Solder Processes

Not suitable for lead free processing

Approved Standards

UL E28476, CSA LR7189

Operating Temperature (°c)

-65 – +105

Temperature Rating

Standard

- Current page: 274 of 320

- Download datasheet (17Mb)

5

274

Tooling shown on this page

is designed to terminate

IDC contacts for various

AMPMODU wire-to-board

connectors. Refer to page

88 to determine the appli-

cable connectors.

Catalog 1307819

Revised 8-08

www.tycoelectronics.com

are metric equivalents.

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

AMPMODU Interconnection System

Application Tooling for Insulation Displacement Crimp (IDC)

Contacts and Connectors

Tube-Fed Ribbon Cable Machine

Designed for bench appli-

cations, this machine is

pneumatically operated and

controlled by a foot pedal. It

terminates connectors onto

end-notched ribbon cable.

*The connectors are sup-

plied in strip form and in

plastic tubes. The machine

consists of three basic sub-

assemblies: a feed track, a

terminating station and a

seating station. The feed

track is a constant force,

2700 lb. Power Unit With

Cable Notching Die

Note: All part numbers are RoHS compliant.

*At a rate of 13-25 positions at a time.

Tube-Fed Ribbon Cable Machine No. 856002-1

2700 lb. Power Unit

No. 312522-1

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

(Continued)

spring-driven unit which

conveys connectors

through the product tube to

the terminating station. The

air-operated terminating sta-

tion positions and termi-

nates contacts onto the

notched cable. The seating

station is manually operated

and seats connector hous-

ings onto the terminated

contacts.

Equipped with a cable

notching die an adapter kit,

this fully pneumatic bench

machine provides the 2700 lb

[12 010N] force required for

end-notching ribbon cable.

It features a grooved cable

support plate, a pressure

plate and a cable stop to

facilitate cable alignment

and positioning during the

notching process.

Notching Dies:

854449-1 (for 24-22 AWG

854449-2 (for 28-26 AWG

[0.08-0.15 mm

[0.2-0.6 mm

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-1106-0803

2

] Wire

2

] Wire

South America: 55-11-2103-6000

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-8706-080-208

Related parts for 104130-3

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

Conn Ejector Header HDR 10 POS 2.54mm Solder RA Thru-Hole

Manufacturer:

TE Connectivity

Datasheet:

Part Number:

Description:

Conn Ejector Header HDR 26 POS 2.54mm Solder RA Thru-Hole

Manufacturer:

TE Connectivity

Datasheet:

Part Number:

Description:

Conn Ejector Header HDR 20 POS 2.54mm Solder RA Thru-Hole

Manufacturer:

TE Connectivity

Datasheet:

Part Number:

Description:

WIRE-BOARD CONN, HEADER, 14POS, 2.54MM

Manufacturer:

TE Connectivity

Datasheet:

Part Number:

Description:

WIRE-BOARD CONN, HEADER, 34POS, 2.54MM

Manufacturer:

TE Connectivity

Part Number:

Description:

High Speed / Modular Connectors 30P HEADER ASSY

Manufacturer:

TE Connectivity

Datasheet:

Part Number:

Description:

High Speed / Modular Connectors REC 6X005P R/A LT B-PLANE HS3

Manufacturer:

TE Connectivity

Datasheet:

Part Number:

Description:

High Speed / Modular Connectors 2MM HM RCPT 50P R/A AU

Manufacturer:

TE Connectivity

Datasheet:

Part Number:

Description:

High Speed / Modular Connectors 2MM HM RCPT 50P R/A AU

Manufacturer:

TE Connectivity

Datasheet:

Part Number:

Description:

Manufacturer:

TE Connectivity

Datasheet:

Part Number:

Description:

Manufacturer:

TE Connectivity

Datasheet:

Part Number:

Description:

Manufacturer:

TE Connectivity

Datasheet:

Part Number:

Description:

Manufacturer:

TE Connectivity

Datasheet: