926681-3 TE Connectivity, 926681-3 Datasheet - Page 6

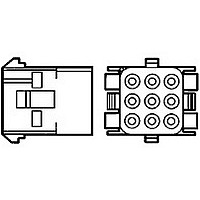

926681-3

Manufacturer Part Number

926681-3

Description

CAP, 12WAY

Manufacturer

TE Connectivity

Series

Universal Mate-N-Lokr

Datasheet

1.926647-3.pdf

(7 pages)

Specifications of 926681-3

Gender

Receptacle

No. Of Contacts

12

No. Of Rows

3

Pitch Spacing

6.35mm

Contact Gender

Socket

Connector Mounting

Free

Contact Material

Bronze

Approval Category

VDE, UL, CSA

Product Type

Connector

Product Line

Universal MATE-N-LOK

Connector Type

Housing

Mount

Free Hanging

Color

Natural

Mating Retention Type

Positive Lock

High Current

No

Current Rating (a)

19

Voltage (vac)

600

Row-to-row Spacing (mm [in])

6.35 [0.250]

Centerline (mm [in])

6.35 [0.250]

Number Of Positions

12

Mating Retention

With

Contact Diameter (mm [in])

2.13 [0.084]

Contact Type

Pin or Socket

Contact Layout

Matrix

Sealable

No

Connector Style

Receptacle

Housing Material

Polyamide - GF

Ul Flammability Rating

UL 94V-0

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

One Piece Housing

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

926681-3

Manufacturer:

TE Connectivity AMP Connectors

Quantity:

2 700

3.9.

3.10.

3.11.

3.12.

3.13.

3.14.

3.15.

3.16.

3.17.

3.18.

Rev A

Mating Force

The force required to mate individual specimens was measured using a tensile/compression device with

a free floating fixture and a rate of travel of 12.7 mm [.5 in] per minute. The maximum average force per

contact was calculated.

Unmating Force

The force required to unmate individual specimens was measured using a tensile/compression device

with a free floating fixture and a rate of travel of 12.7 mm [.5 in] per minute. The minimum average force

per contact was calculated.

Contact Insertion Force

Contact insertion force was measured by applying an increasing force to each contact until the contact

was properly seated in the housing.

Contact Retention Force

An axial load of 66.7 N [15 lbf] was applied to standard contacts and 111.2 N [25 lbf] for high retention

contacts and held for 60 seconds. The force was applied in a direction to cause removal of the contacts

from the housing.

Crimp Tensile

The force load was applied to each specimen using a tensile/compression device with the rate of travel

at 25.4 mm [1 in] per minute.

Durability

Specimens were manually mated and unmated 50 times.

Housing Panel Retention

Specimens were mounted rigidly into a test panel. An axial load of 333.6 N [75 lbf] was applied to each

end of the specimen in a direction which would cause the specimen to dislodge from the panel.

Housing Lock Strength

An axial load of 133.4 N [30 lbf] was applied to mated specimens in a manner which would cause the

specimen locking latches to disengage.

Thermal Shock

Mated specimens were subjected to 25 cycles of thermal shock with each cycle consisting of 30 minute

dwells at -55 and 85

Humidity/temperature Cycling

Mated specimens were exposed to 10 cycles of humidity/temperature cycling. Each cycle lasted 24

hours and consisted of cycling the temperature between 25 and 65

humidity. During 5 of the first 9 cycles, the specimens were exposed to a cold shock of -10

and vibration.

/

C . The transition between temperatures was less than 1 minute.

/

C twice while maintaining high

/

C for 3 hours

110-213

6 of 7