1217955-1 TE Connectivity, 1217955-1 Datasheet - Page 4

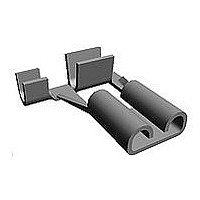

1217955-1

Manufacturer Part Number

1217955-1

Description

.187 FAST FL AMVAR 0157 TPBR

Manufacturer

TE Connectivity

Specifications of 1217955-1

Product Type

Terminal

Terminal Type

Receptacle

Mating Area Interface Dimensions (mm [in])

4.75 x 0.81 [.187 x .032]

Receptacle Style

Flag

Insulation Support

Insulation Support

Wire/cable Type

Magnet Wire

Insulation Diameter (mm [in])

0.51-1.02 [.020-.040]

Insertion Force

Normal

Finish

Tin

Crimp Type

F-Crimp

Proprietary Name

AMPLIVAR

Board Mount

No

Weld Tab

Without

Wire Range (mm [awg])

0.80-2.00² [18-14]

Stock Thickness (mm [in])

0.41 [0.016]

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Strip

|

|

|

|

3.6.

4.

4.1.

Rev D

Product Qualification and Requalification Test Sequence

QUALITY ASSURANCE PROVISIONS

Qualification Testing

A.

B.

Specimen Selection

Specimens shall be prepared in accordance with applicable Instruction Sheets and shall be

selected at random from current production. Each test group shall consist of a minimum of 6

specimens. Each specimen ID shall each consist of 24 specimens of the following wire type and

crimp heights: 24 AWG Al and CU magnet wire at .041 crimp height; 20 AWG Al and Cu magnet

wire at .046 crimp height; 18.5 AWG Al and Cu magnet wire at .053 crimp height; 16.5 AWG Al

and Cu magnet wire at .059 crimp height; 17.5 AWG Al and Cu magnet wire at .058 crimp height;

14.5 AWG Al and Cu magnet wire at .070 crimp height; 14.5 AWG Al magnet wire and 18 AWG

lead wire at .078 crimp height; 15.5 AWG Al magnet wire and 18 AWG lead wire at .074 crimp

height; 18 AWG Cu magnet wire and 18 AWG lead wire at .066 crimp height; 22.5 and 18 AWG

Al magnet wire at .057 crimp height; 17.5 and 21 AWG Al magnet wire at .059 crimp height;18

and 21 AWG Al magnet wire at .059 crimp height; and 20 AWG Al and Cu magnet wire at .049

crimp height.

Test Sequence

Qualification inspection shall be verified by testing specimens as specified in Figure 2.

NOTE

(a)

(b)

Initial examination of product

Low level contact resistance

Temperature rise vs current

Current cycling

Vibration

Mechanical shock

Durability

Mating force

Unmating force

Termination tensile strength

Humidity-temperature cycling

Temperature life

Final examination of product

See paragraph 4.1.A.

Numbers indicate sequence in which tests are performed.

Test or Examination

Figure 2

3,7

1

1

5

6

4

2

8

9

Test Sequence (b)

Test Group (a)

2,8

4,9

10

2

1

7

3

5

6

3

1

2

3

2,4

4

1

3

5

108-2086

4 of 6