1318917-1 TE Connectivity, 1318917-1 Datasheet - Page 5

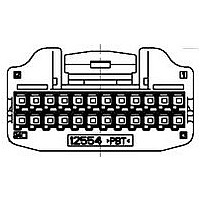

1318917-1

Manufacturer Part Number

1318917-1

Description

025 ECU PLUG HSG ASSY 24P

Manufacturer

TE Connectivity

Specifications of 1318917-1

Product Type

Connector

Connector Type

Housing

Plug Configuration

025

Mount

Free Hanging

Number Of Positions

24

Wire Range/signal (mm²)

CAVS 0.22-0.5, AVSSH-f 0.3-0.5, AVSS/CAVUS 0.3-0.5

Contact Type

Receptacle

Connector Style

Plug

Housing Material

PBT - GF

Housing Color

Natural

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Applies To

Wire/Cable

Packaging Method

Bag, Box

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

1318917-1

Manufacturer:

TE

Quantity:

5 000

Company:

Part Number:

1318917-1

Manufacturer:

TE Connectivity AMP Connectors

Quantity:

1 121

Rev. H6

3.5.23

3.5.24

3.5.25

3.5.26

3.5.27

3.5.28

3.5.19

3.5.20

3.5.21

3.5.22

Handling Ergonomics

Retention Force

of Tab

Resistance to

soldering heat

Thermal Shock

Humidity

Industrial Gas (SO

Temperature Life

(Heat Aging)

Resistance to Cold

Humidity-Temperature

Cycling

Dust Bombardment

(Steady State)

2

)

No abnormalities allowed in

manual mating/unmating

handling.

20N Min. (PBT housing)

15N Min. (SPS housing)

Application to SPS housing only.

No gap with PCB and omission of

screw.

Retention Force of Tab : 15N Min.

Satisfy requirements of test

item on the “3.6 sequence”.

Satisfy requirements of test

item on the “3.6 sequence”.

Current Leakage

Satisfy requirements of test

item on the “3.6 sequence”.

Satisfy requirements of test

item on the “3.6 sequence”.

Satisfy requirements of test

item on the “3.6 sequence”.

Satisfy requirements of test

item on the “3.6 sequence”.

Satisfy requirements of test

item on the “3.6 sequence”.

: 3mA Max.

Product Specification

Environmental Requirements

Fig.3 (To be continued)

Manually operated.

Measure the retention force between

housing and tab contact.

Operation speed : 100mm/min

Test connector solder dipped after

mounted on PCB with screw.

It should be checked and measured

after test connector become room

temperature.

Solder temperature : 260±5℃

Immersion duration : 10±1sec.

TE Spec.109-5204 Condition B

-40℃/30min., 100℃/30min.

Making this a cycle, repeat 1000

cycles.

Monitor resistance-variation at

closed circuit current of 10mA during

the test.

TE Spec. 109-5103

90~95%R. H. , 60℃ , 96hours

Monitor current leakage during the

test.

TE Spec. 109-5105

Unmated connector

SO

25℃, 96 hours

TE Spec. 109-5107

120℃, 120hours

TE Spec. 109-5104

-40℃, 120hours

TE Spec. 109-5108

Condition : Fig. 10

Monitor resistance-variation at

closed circuit current of 10mA during

the test.

Subject JIS R 5210 cement blow of

1.5kg per 10 seconds in 15 minutes

intervals for 8 cycles, with

mating/unmating per 2 cycles.

TE Spec. 109-5110

Making this condition a cycle,

Repeat 10 cycles.

2

Gas : 25ppm, 75% R. H.

108-5668

5 of 12