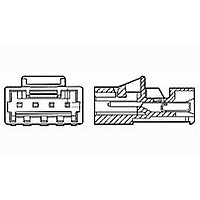

3-644807-9 TE Connectivity, 3-644807-9 Datasheet

3-644807-9

Specifications of 3-644807-9

Related parts for 3-644807-9

3-644807-9 Summary of contents

Page 1

... The maximum rated current that can be carried by this product is limited by the NOTE maximum operating temperature of the housings (105°C) and the temperature rise of the contacts (30° C). Variables which shall be considere d for each application are: wire size, connector size, contact material, and ambient temperature. ! Operating Temperature: -55 to 105° ...

Page 2

... Procedure Visual, dimensional and functional per applicable inspection plan. TE Spec 109-6, Condition A. Subject mated connectors assembled in housing open circuit at 100 ma maximum. See Figure 3. TE Spec 109-25. Measure potential drop of mated contacts assembled in housing. Calculate resistance. See Figure 3. TE Spec 109-28-4. Test between adjacent circuits of mated connector assemblies ...

Page 3

... Apply force perpendicular to axis of wire on samples without cover. TE Spec 109-21-1, Condition A. 10-55-10 Hz traversed in 1 minute at 0.06 inch total excursion. 2 hours in each of 3 mutually perpendicular planes. TE Spec 109-27. Manually mate and unmate connector assemblies for 25 cycles. Mount connector in fixture. ...

Page 4

... See paragraph 4.1.A. NOTE (b) Numbers indicate sequence in which tests are performed. (c) One half of the samples shall be subjected to the straight tensile test and the remaining half to the perpendicular tensile test. Rev F Test Group ( Test Sequence (b) 1 2,4 2,4 1,3 2,5 1 Figure 2 108-1065 1 ...

Page 5

... If product failure occurs, corrective action shall be taken and samples resubmitted for qualification. Testing to confirm corrective action is required before resubmittal. 4.3. Quality Conformance Inspection The applicable quality inspection plan shall specify the sampling acceptable quality level to be used. ...

Page 6

... A 1 foot minimum length of continuous lead for heat dissipation. NOTE 2. Termination resistance equals millivolts divided by test current less resistance of 6 inches of wire. Temperature and Resistance Measurement Points Rev F Figure 3 108-1065 ...

Page 7

Rev F Figure 4 Terminal Temperature vs Current/Circuit 24 Circuit Assembly 108-1065 ...