4-647630-1 TE Connectivity, 4-647630-1 Datasheet - Page 2

4-647630-1

Manufacturer Part Number

4-647630-1

Description

11P MTA100 HRD ASSY F/L LF

Manufacturer

TE Connectivity

Specifications of 4-647630-1

Connector Type

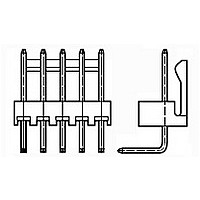

Header

Product Line

MTA-100

Pcb Mounting Orientation

Right Angle

Right Angle Bending Side

Front

Pcb Mount Retention

Without

Mating Connector Lock

With

Four Points Of Contact

Without

Shrouded

No

Mounting Ears

Without

Mating Connector Lock Type

Friction Lock

Post Size (mm [in])

0.64 [.025]

Panel Mount Retention

Without

Mating Post Length (mm [in])

7.37 [0.290]

Current Rating (a)

5

Voltage Rating (vac)

250

Solder Tail Contact Plating

Tin

Termination Post Length (mm [in])

3.56 [0.140]

Number Of Positions

11

Centerline (mm [in])

2.54 [0.100]

Narrow

No

Post Number(s) Omitted

None

Solder Tail Contact Material

Copper Alloy

Contact Type

Pin

Contact Shape

Square

Contact Plating, Mating Area, Material

Tin

Contact Base Material

Copper Alloy

Connector Style

Plug

Housing Color

Black

Mating Alignment

Without

Ul Flammability Rating

UL 94V-0

Housing Material

Thermoplastic - GF

Backwall/post Interruption(s)

Without

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Wave solder capable to 240°C

Rohs/elv Compliance History

Always was RoHS compliant

Applies To

Printed Circuit Board

Application Use

Wire-to-Board

3.3.

3.4.

3.5.

Examination of product.

Termination resistance.

Insulation resistance.

Dielectric withstanding voltage.

Temperature rise vs current.

Solderability.

Termination tensile strength,

parallel, unmated.

Termination tensile strength,

perpendicular, unmated.

Rev H

Ratings

!

!

!

Performance and Test Description

Product is designed to meet the electrical, mechanical and environmental performance requirements

specified in Figure 1. Unless otherwise specified, all tests shall be performed at ambient environmental

conditions per Test Specification 109-1.

Test Requirements and Procedures Summary

Test Description

Voltage: 250 volts AC

Current: See Figure 4 for applicable current carrying capability

Temperature:

-55 to 105° C

Meets requirements of product

drawing and Application Spec 114-

1019.

6 milliohms maximum initial.

∆R 10 milliohms maximum.

5000 megohms minimum initial.

750 vac at sea level.

1 minute hold with no breakdown or

flashover.

30° C maximum temperatur e rise at

specified current.

Solderable area shall have

minimum of 95% solder coverage.

Wire Size

Wire Size

AWG

AWG

28

24

22

28

24

22

MECHANICAL

Figure 1 (cont)

ELECTRICAL

Requirement

Pounds Minimum

Pounds Minimum

Slot Tensile

Slot Tensile

12

4

5

1

1

3

Visual, dimensional and functional

per applicable quality inspection

plan.

TE 109-6-1.

Subject mated contacts assembled

in housing to 50 mv maximum open

circuit at 100 ma maximum.

See Figures 3 and 5.

TE Spec 109-28-4.

Test between adjacent contacts of

unmated samples.

TE Spec 109-29-1.

Test between adjacent contacts of

unmated samples.

TE Spec 109-45-2.

Measure temperature rise vs

current.

See Figures 4 and 5.

TE Spec 109-11-2.

Subject contacts to solderability.

TE Spec 109-16.

Determine slot tensile at maximum

rate of 1 inch per minute. Pull

parallel to terminated wire.

See Figure 6.

TE Spec 109-16.

Determine slot tensile at maximum

rate of 1 inch per minute. Pull

perpendicular to terminated wire.

See Figure 6.

Procedure

108-1050

2 of 9