641144-3 TE Connectivity, 641144-3 Datasheet

641144-3

Specifications of 641144-3

Related parts for 641144-3

641144-3 Summary of contents

Page 1

... SCOPE 1.1. Content This specification covers performance, tests and quality requirements for the TE Connectivity (TE) MTA 156 connector/header system. This system is mass terminated using insulation displacement technology on .156 inch centerlines and mates with .045 inch square or round posts providing interconnection between wires and posts mounted on printed circuit boards. Terminations are designed for 26 through 18 AWG wire having ...

Page 2

Ratings ! Voltage: 600 volts AC ! Current: See Figure 4 for applicable current carrying capability ! Temperature: -55 to 105° C 3.4. Performance and Test Description Product is designed to meet the electrical, mechanical and environmental performance requirements ...

Page 3

Test Description Termination tensile strength, perpendicular, unmated. Vibration, sinusoidal. Vibration, random. Mechanical shock. Durability. Mating force. Unmating force. Thermal shock. Rev J Requirement Wire Size Slot Tensile AWG Pounds Minimum 26 1.3 24 1.3 22 3.4 20 4.0 18 4.6 ...

Page 4

Test Description Humidity/temperature cycling. Temperature life. Mixed flowing gas. Shall meet visual requirements, show no physical damage and shall meet requirements of NOTE additional tests as specified in Test Sequence in Figure 2. Rev J Requirement See Note. See Note. ...

Page 5

Product Qualification and Requalification Test Sequence Test or Examination Examination of product Termination resistance Insulation resistance Dielectric withstanding voltage Temperature rise vs current Solderability Tensile strength Vibration, sinusoidal Vibration, random Mechanical shock Durability Mating force Unmating force Thermal shock ...

Page 6

QUALITY ASSURANCE PROVISIONS 4.1. Qualification Testing A. Sample Selection Samples shall be prepared in accordance with applicable Instruction Sheets and shall be selected at random from current production. Unless otherwise required for the test procedure, test groups 1, 2, ...

Page 7

Termination resistance equals millivolts divided by test current less resistance of wire length. NOTE (b) After wave soldering, printed circuit board and posts shall be cleaned to remove all flux and contaminates. Termination Resistance & Temperature Rise Measurement Points ...

Page 8

Percent Connector Loading (Tin plated 10 position in-line connector) Single Contact 50 See Note (a) 100 (a) Every other (odd) position energized NOTE (b) To determine acceptable current carrying capacity for the percentage connector loading and wire gage indicated, use ...

Page 9

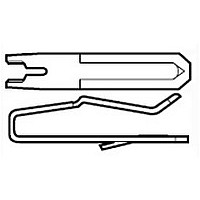

Rev J Figure 5 Termination Tensile Strength 108-1051 ...

Page 10

Rev J Figure 6 Vibration & Mechanical Shock Mounting Fixture (Use For Reference Only) 108-1051 ...