643818-7 TE Connectivity, 643818-7 Datasheet - Page 3

643818-7

Manufacturer Part Number

643818-7

Description

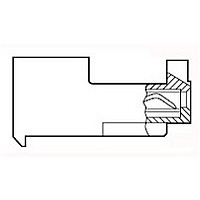

WIRE-BOARD CONN RECEPTACLE, 7POS, 3.96MM

Manufacturer

TE Connectivity

Specifications of 643818-7

Peak Reflow Compatible (260 C)

No

External Width

1.092"

Body Material

Nylon

Size

0.355 H X 1.092 W X 0.725 " D

Wire Size (awg)

20

Leaded Process Compatible

No

Rohs Compliant

No

Connector Type

Connector Assembly

Connector Design

Closed End

Product Line

MTA-156

Termination Method To Wire/cable

IDC Standard

Wire Size (mm² [awg])

0.5-0.6² [20]

Mating Connector Lock

With

Four Points Of Contact

Without

Shrouded

No

Mounting Ears

Without

Mating Connector Lock Type

Locking Ramp

Panel Mount Retention

Without

Current Rating (a)

7

Voltage Rating (vac)

600

Solder Tail Contact Plating

Tin-Lead

Number Of Positions

7

Centerline (mm [in])

3.96 [0.156]

Narrow

No

Post Number(s) Omitted

None

Cable Exit Angle

90°

Contact Type

Socket

Contact Plating, Mating Area, Material

Tin-Lead

Contact Base Material

Copper Alloy

Connector Style

Receptacle

Housing Color

Yellow

Mating Alignment

With

Ul Flammability Rating

UL 94V-2

Housing Material

Nylon

Mating Alignment Type

Polarizing Tab

Rohs/elv Compliance

Not ELV/RoHS compliant

Lead Free Solder Processes

Not relevant for lead free process

Applies To

Wire/Cable

Application Use

Wire-to-Board

Rev F

Tensile, perpendicular.

Vibration.

Durability.

Contact retention.

Mating force.

Unmating force.

Thermal shock.

Humidity-temperature cycling.

NOTE

Test Description

Shall meet visual requirements, show no physical damage, and shall meet requirements of

additional tests as specified in the Test Sequence in Figure 2.

No discontinuities greater than 1

microsecond.

See Note.

See Note.

5.0 pounds minimum.

1.6 pounds maximum initial.

0.2 pound minimum final.

See Note.

See Note.

Wire Size

(AWG)

26

24

22

20

18

ENVIRONMENTAL

Figure 1 (end)

Requirement

(Lb minimum)

Slot Tensile

1.3

1.3

3.4

4.0

4.6

TE Spec 109-16.

Determine slot tensile at a rate of 1

inch per minute. Apply force

perpendicular to axis of wire on

samples without cover.

TE Spec 109-21-1, Condition A.

10-55-10 Hz traversed in 1 minute

at 0.06 inch total excursion. 2 hours

in each of 3 mutually perpendicular

planes.

TE Spec 109-27.

Manually mate and unmate

connector assemblies for 25 cycles.

Mount connector in fixture.

TE Spec 109-30.

Pull on contact using special cut-

away housing.

TE Spec 109-42.

Measure force necessary to mate

connector assembly with locking

latches intact, a distance of .150

inch from point of initial contact

using free floating fixtures at a rate

of 0.5 inch per minute.

Calculate force per contact.

TE Spec 109-42.

Measure force necessary to

unmate connector assembly with

locking latch removed at a rate of

0.5 inch per minute.

Calculate force per contact.

TE Spec 109-22.

Subject mated connectors to 25

cycles between -55 and 85° C.

TE Spec 109-23-5, Condition B.

Subject mated connectors to 10

humidity-temperature cycles

between 25 and 65° C at 95% RH

with low frequency vibration and

-10° C cold shock after any 5 cycles.

Procedure

108-1065

3 of 7