148384-5 TE Connectivity, 148384-5 Datasheet - Page 16

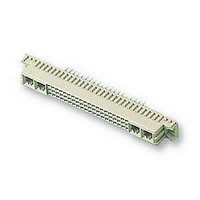

148384-5

Manufacturer Part Number

148384-5

Description

SOCKET, DIN41612, STRAIGHT, M, 24+8WAY

Manufacturer

TE Connectivity

Datasheet

1.148384-5.pdf

(18 pages)

Specifications of 148384-5

Connector Type

Pitch Spacing

No. Of Contacts

32

Gender

Receptacle

No. Of Rows

3

Rows Loaded

A + B + C

Contact Termination

Through Hole

Contact Material

Phosphor Bronze

Contact

RoHS Compliant

Pitch Spacing

2.54mm

Contact Plating

Gold

Rohs Compliant

Yes

Product Series

Type M

Mount Angle

Vertical

Post Type

Compliant Post

Din Level

II

Loaded With Single Contacts Only

Yes

Color

Gray

Toolless (flat Rock)

Yes

Termination Post Length (mm [in])

6.00 [0.236]

Solder Tail Contact Plating

Tin-Lead over Nickel

Number Of Signal Contacts

24

Contact Type

Socket

Number Of Power Or Coaxial Contacts

8

Preloaded

Yes

Contact Configuration

Coaxial, Power

Contact Base Material

Phosphor Bronze

Contact Plating, Mating Area, Material

Gold Flash over Palladium Nickel

Connector Style

Receptacle

Housing Material

Thermoplastic - GF

Ul Flammability Rating

UL 94V-0

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Pcb Thickness, Recommended (mm [in])

1.57 [0.062]

Application

Board-to-Board Power

5.3. Seating Tool

Seating tools must be used in manual or power assist units with sufficient ram surface and the capability of

applying insertion force per contact. The seating tools align the components for proper seating and are

specifically designed for the different types of Eurocard connectors. Seating tools, connector types, and

instruction sheets are shown in Figure 15.

5.4. Pushing Plate

A pushing plate (customer supplied) must be used to seat vertical receptacles with ACTION PIN thin stock

contacts and square stock contacts in connectors that do not require special tooling. The pushing plate must

be of minimum length and width equal to full top dimensions of the receptacle. The larger the pushing plate, the

less critical the alignment during seating. When seating connector, the pushing plate must move in a straight,

vertical line, and its bottom surface must be parallel to the top of the pc board support or template when force

is applied. See Figure 15.

16 of 18

Seating Tool 535072- - 1

for Type C Receptacle Connectors

(408- - 9623)

Seating Tool 148090- - [ ]

for Type M Receptacle Connectors

(408- - 9623)

Seating Tools 768211- - [ ]

for Type R Vertical Pin Connectors

without MFBL Contacts (408- - 9740)

Programmable Seating Tools 768216- - [ ]

for Type R Vertical Pin Connectors

with MFBL Contacts (408- - 9894)

NOTE

i

The force used to seat Eurocard connectors with square stock contacts shall not exceed 177.93 N [40 lbs] per contact.

Seating force for connectors with ACTION PIN thin stock contacts shall not exceed 88.96 N [20 lbs] per contact.

PC Board

Support (Anvil)

PC Board

Pushing Plate for Vertical

Connectors Not Requiring

Special Tooling (Customer

Supplied)

Figure 15

Vertical

Receptacle

Applicator

Machine Ram

114- 9014

Rev G