HEN-1.5/25-D12M-C Murata Power Solutions Inc, HEN-1.5/25-D12M-C Datasheet - Page 8

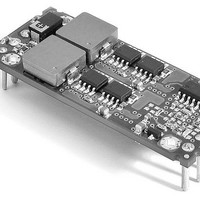

HEN-1.5/25-D12M-C

Manufacturer Part Number

HEN-1.5/25-D12M-C

Description

DC/DC Converters & Regulators 37.5W 12V-1.5V 25A Eighth-Brick

Manufacturer

Murata Power Solutions Inc

Series

HENr

Datasheet

1.HEN-1.525-D12M-C.pdf

(11 pages)

Specifications of HEN-1.5/25-D12M-C

Output Power

38 W

Input Voltage Range

10.2 V to 13.8 V

Number Of Outputs

1

Output Voltage (channel 1)

1.5 V

Output Current (channel 1)

25 A

Package / Case Size

Eighth Brick

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

HEN-1.5/25-D12M-C

Heatsink Installation

Heatsinks, in combination with adequate airflow, significantly extend the

power-handling capability of DATEL power supplies and add a safety

margin. Please study the Derating Curves to understand the increased

thermal capacity available when a heatsink is installed.

DATEL will supply our custom-designed heatsinks already installed. If

preferred, users may also purchase the heatsink assembly separately. If so,

please carefully follow the installation instructions below to avoid damage

to the DC/DC converter. Contact DATEL if you need assistance. The follow-

ing procedures require adequate mechanical skills.

Installation has several goals:

1. Insure positive thermal contact between heat-generating circuit

2. Avoid mechanical stress to the printed circuit board and on-board

3. Fasten the heatsink securely so that vibration in the application will not

4. Avoid stripping threads in the aluminum heatsink.

Thermal Pads

The heatsink is supplied with one or more thermal mounting pads which

provide a heat transfer path with low thermal resistance between power

components and the heatsink. DATEL does NOT recommend "thermal

grease" or thermal mounting compounds.

Mounting Screws

DATEL power supplies are precision miniature electronic assemblies

fabricated on multiple circuit board layers. Excessive pressure or incor-

rect mechanical stress may distort the board layers, apply too much force

on components or even break small connections. Such fractures may not

be visible with the naked eye. It is very important to use the assembly

sequence below. We want both a correct sequence and the right amount

of torque. This assembly sequence is similar to engine cylinder heads

(progressive torquing of diagonally alternating bolts).

A tiny amount of medium-strength (blue) Loctite ® thread assembly adhe-

sive or equivalent is acceptable in high vibration applications. The threads

must be degreased for Loctite to work. Do not soak the threads with

Loctite. Also, be aware that Loctite will soften at higher temperatures.

components and the heatsink.

components.

loosen the mounting screws. Note that some heat may be conducted

through the screws.

www.murata-ps.com

Correct assembly requires a precision low range torque wrench.

[1] Make sure all the thermal pads have been securely installed. Mount the

[2] Tighten the first screw only to 50% of maximum final torque (see the

[3] Tighten the screw in the diagonally opposite corner to 50% torque.

[4] Tighten the screw adjacent to the first screw to 50% torque.

[5] Repeat steps [2] to [4], tightening all screws to their maximum torque.

[6] Thoroughly retest the power supply before committing it to application.

WARNING: Incorrect assembly sequence and/or excessive torque may

damage the converter.

For attachment screws, the following maximum final torques must be used:

heatsink using the screws supplied. See the assembly diagram. Do not

tighten the screws yet.

table below).

Single Output, Non Isolated, 12VIN, 0.8-5VOUT

#2-56 thread

#4-40 thread

#6-32 thread

Screw Size

#M3 thread

Technical enquiries email: sales@murata-ps.com, tel:

25 Amp, High di/dt DC/DC Converters

Maximum Assembled Torque

2.5 inch-pounds maximum

5.5 inch-pounds maximum

6.0 inch-pounds maximum

9.6 inch-pounds maximum

HEN D12 Models

MDC_HEN-D12.B01 Page 8 of 11

+1 508 339 3000