9-520272-2 TE Connectivity, 9-520272-2 Datasheet - Page 4

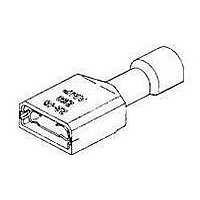

9-520272-2

Manufacturer Part Number

9-520272-2

Description

Terminals 110 ULTRA-FAST RCPT 22-18 TPBR

Manufacturer

TE Connectivity

Specifications of 9-520272-2

Product

Fastons

Wire Size (awg)

22-18

Insulation

Insulated

Color

Black

Gender

Female

Contact Plating

Tin

Contact Material

Brass

Termination Style

Crimp

Insulation Material

Nylon

Mounting Angle

Straight

Mounting Method

Wire

Number Of Positions / Contacts

1

Number Of Rows

1

Terminal Type

Receptacle

Proprietary Name

Ultra-Fast

Receptacle Style

Straight

Mating Area Interface Dimensions (mm [in])

2.79 x 0.81 [.110 x .032], 3.18 x 0.81 [.125 x .032]

Insulation Diameter (mm [in])

3.05 [.120] Max.

Insulation Support

Non-Insulation Support

Finish

Tin

Wire Range (mm [awg])

0.30-0.90² [22-18]

Fully Insulated

Yes

Ul Flammability Rating

UL 94V-2

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Strip

Lead Free Status / Rohs Status

Details

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

9-520272-2

Manufacturer:

TE

Quantity:

20 000

3.6.

Rev D

Exam ination of Product

Dielectric W ithstanding Voltage,

Test Condition A

Dielectric W ithstanding Voltage,

Test Condition C

Dielectric W ithstanding Voltage,

Receptacle, Tab Entry Position

Heating (Tem perature Rise)

Heat Cycling (Current Cycling)

Pull Out (Crim p Tensile)

Secureness of Insulation

(Unassem bled)

Secureness of Insulation

(Assem bled)

Engagem ent-Disengagem ent

(Engaging-Separating)

Heat Age, 136 C

Heat Age/Hum idity

Term inal Tests and Sequences

NOTE

(Plain Brass)

.205/.187

Tab Size

Test or Exam ination

.250

.110

(a)

(b)

(c)

See paragraph 4.1.A.

Numbers indicate sequence in which tests are performed.

Uncrimped terminals and wires in test groups 4 and 11 shall be conditioned in the

environments indicated. After conditioning, each sample is crimped to the appropriate

wire and the electrical or mechanical test is performed.

Term inal

Plating

Tin

Engagem ent and Disengagem ent Forces

Individual

Insertion

(m ax)

First

17

15

12

1

1

2

3

Individual

2

1

2

3

(m ax)

17

20

14

Figure 2

Figure 3

3

1

3

2

3(c)

W ithdrawal

4

1

2

Average

(m in)

First

Force (pounds)

5

5

3

Test Sequence (b)

5

1

2

Test Group (a)

Individual

6

1

2

(m in)

3

3

2

1

7

2

1

8

2

Average

(m in)

4

3

2

W ithdrawal

1

9

3

2

Sixth

10

1

3

2

Individual

(m in)

3(c)

3

2

1

11

1

2

108-2043

12

1

2

4 of 5