66L055 AIRPAX, 66L055 Datasheet - Page 2

66L055

Manufacturer Part Number

66L055

Description

91F9379

Manufacturer

AIRPAX

Datasheet

1.66F045.pdf

(4 pages)

Specifications of 66L055

Temperature Accuracy ±

5°C

Body Material

PPS (Polyphenylene Sulfide)

Temperature Differential ±

4°C

Mounting Type

PC Board Thru Hole

Reset Temperature Min

30°C

Contact Rating

1A At 48VDC

Rohs Compliant

Yes

Color

Black

Operating Temperature Min

55°C

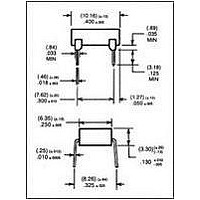

( 10.16 ± .13 )

.400 ± .005

SPECIFICATIONS

I

I

I

I

I

I

I

I

I

I

I

I

I

Airpax 6600 Series Thermostats

Standard 8 PIN D.I.P. Configuration*

( 7.46 ± .25 )

.018 ± .003

( .46 ± .08 )

.300 ± .010

( .84 )

.033

Contact Resistance: 50 Milliohms max.

Contact Ratings: (see *Special Requirements)

Approved per VDE 0631/12.83

Cycles

30,000

30,000

100,000

CSA Certified LR25561 and UL Recognized E36687

Cycles

30,000

30,000

100,000

100,000

Ambient Temperature Range: -55°C to 160°C

Contact Operations: Either open on rise or close on rise

Operating Temperature Range:

40°C (104°F) to 120°C (248°F)

Standard Operating Temperature Tolerance:

±5°C (±9°F) Nominal operating temperature settings

in 5°C (9°F) increments

US Patent No: 4,620,175

Short Term Exposure Limit: 260°C (500°F), 10 sec.

Long Term Exposure Limit: -55°C (-67°F) to 160°C (320°F)

Dielectric Strength: 1480 VAC 60Hz, 1 second

terminals to case

Insulation Resistance: 100 Megohms at 500 VDC

Contact Bounce - make: 3 ms max.

Weight: Approximately 0.45 grams

MIN

PIN Number Identification Does Not Appear on Part

Voltage

48 VDC Test, Class 1

120 VAC Test, Class I

5 VDC Test, Class II

Voltage

48 VDC

120 VAC

5 VDC

5 VDC

.050 ± .005

( 1.27 ± .13 )

Epoxy Seal

( 3.18 )

( .89 )

.035

.125

MIN

MIN

.010 ± .0005

Amps (resistive)

1 A

1 A

0.02 A

Amps (resistive)

1 A

1 A

0.001 A

0.02 A

( .25 ± .013 )

( 8.26 ± 6.4 )

.325 ± .025

.250 ± .005

( 6.35 ± .13 )

( 3.30 )

.130

I

I

I

I

I

I

MATERIALS

I

I

I

I

I

*Special Requirements: Please consult factory for special part

number if VDE, surface mount and/or tape and reel is required.

(Note:Tape and reel available with surface mount only)

Temperature Calibration is checked at Airpax with precision

test equipment traceable to the US National Institute of Standards

and Technology and Proven Methods. Because customer checking

methods may differ, a typical variance allowed for correlation is

±2°F (±1.1°C).

+

-

+

-

.005

.010

.25

.13

Seal: Epoxy sealed for wave soldering and cleaning.

Moisture proof per Airpax Spec. S-722 (unit will not leak while

submerged in 9" of water for a minimum of two minutes).

Chemical Resistance: Both the base and the unit are

resistant to water, salt, alcohol, ammonia, trichlorethane,

and most other organic solvents.

Vibration: Per Mil-Std-202, Method 204D,

Test Condition D, 10-2,000 Hz.

Shock: Per Mil-Std-202, Method 213,Test Condition C,

100 G’s, 6 milliseconds, ⁄/™ sine wave.

R

Per Mil-Std-202F, Method 210A,Test Condition E.

Mechanical Life

Seal: High temperature epoxy

Base: PPS (Polyphenylene Sulfide), 94 VO rated

Terminals: 65% Copper, 18% Nickel

Contacts: Gold-plated or overlay, silver cross bar

Bracket: Nickel-plated copper or high pressure

laminated plastic

esistance to Soldering Heat:

Schematic For

Schematic For

Open on Rise

Close on Rise

Operation

Operation

: 1KK operations

( 10.16 ± .13 )

.400 ± .005

Surface Mount Configuration*

( 1.27 ± .13 )

.050 ± .005

( 7.62 ± .13 )

.300 ± .005

Epoxy Seal

( 3.30 )

.130

.018 ± .003

.018 ± .003

( .46 ± .08 )

( .46 ± .08 )

+

-

+

-

.005

.010

.25

.13