53892-7 TE Connectivity, 53892-7 Datasheet - Page 8

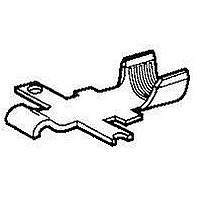

53892-7

Manufacturer Part Number

53892-7

Description

Power to the Board CONTACT CRIMP 18-12 Series 1

Manufacturer

TE Connectivity

Series

Series Ir

Specifications of 53892-7

Product Type

Contacts

Termination Style

Crimp

Contact Plating

Gold (30)

Contact Material

Copper

Wire Gauge Range

18-12

Wire Size (awg)

18-12

Termination Method To Wire/cable

Crimp

Ul File Number

E28476

Csa File Number

LR7189

Wire/cable Type

Discrete Wire

Make First / Break Last

No

Contact - Rated Current (a)

31

Operating Voltage Reference

AC

Operating Voltage (vac)

600

Wire/cable Size (awg)

12 – 18

Wire/cable Size (mm²)

0.811 – 3.09

Wire/cable Size (cma)

1,601 – 6,098

Profile Height (y-axis) (mm [in])

3.05 [0.120]

Length (x-axis) (mm [in])

18.29 [0.720]

Width (z-axis) (mm [in])

3.76 [0.148]

Underplate Material Thickness (µm [?in])

1.27 [50.000]

Contact Type

Pin/Socket

Contact Plating, Mating Area, Material

Gold

Contact Plating, Mating Area, Thickness (µm [?in])

0.762 [30]

Contact Base Material

Copper

Contact Design

Spring Latch

Underplate Material

Nickel

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Vde Tested

No

Agency/standard

UL, CSA

Ul Rating

Recognized

Csa Certified

Yes

Operating Temperature (°c [°f])

-40 – +75 [-40 – +167]

Applies To

Wire/Cable

Accepts Wire Insulation Diameter, Range (mm [in])

0.864 – 0.914 [0.034 – 0.036]

Accepts Wire Material

Copper

Application Use

Wire-to-Wire

Contact Transmits (typical Application)

Power

Packaging Method

Loose Piece

Lead Free Status / Rohs Status

Details

Rev B

NOTE

NOTE

(a)

(b)

(a)

(b)

(c)

Unless specifically permitted within NEC, overcurrent protection for the following conductor

types shall not be exceeded.

1.

2.

3.

4.

To determine acceptable current carrying capacity for percentage connector loading and wire

gage indicated, use Multiplication Factor (F) from above chart and multiply it times Base

Rated Current for a single circuit at maximum ambient operating temperature as shown in

Figure 5A.

Thermocouples shall be spot welded to contact near intersection of tongue and barrel as

shown and coated with thermal conductive epoxy.

Thermocouple shall exit housing by running down side of wire barrel.

Printed circuit board shall be modified to allow thermocouple wire to pass through boards.

7 amperes for 18 AW G copper wire

10 amperes for 16 AW G copper wire

15 amperes for 14 AW G copper wire

20 amperes for 12 AW G copper wire

Percent Connector

Single Contact

Loading

100

50

Therm ocouple Mounting

Current Rating

Figure 5B

Figure 6

.56

.51

.43

18

W ire Size AW G

.71

.64

.55

16

.85

.66

.78

14

.91

.78

12

1

108-11026

8 of 9