2198484-1 TE Connectivity, 2198484-1 Datasheet - Page 5

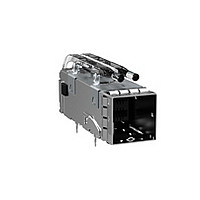

2198484-1

Manufacturer Part Number

2198484-1

Description

Manufacturer

TE Connectivity

Specifications of 2198484-1

Product Type

Cage, Connector

Gender

Receptacle

Number Of Ports

1

Pcb Mounting Orientation

Right Angle

Plug Configuration

Mini-SAS HD

Receptacle Configuration

Mini-SAS HD

Pcb Mount Style

Through Hole Press Fit

Pcb Mount Retention

With

Keyed

No

Stackable

No

Termination Post Length (mm [in])

1.64 [0.065]

Height Above Pc Board (mm [in])

16.44 [0.647]

Number Of Positions

36

Number Of Rows

Dual

Pcb Mount Retention Type

M2 Screws

Mount Type

PC Board (Direct Mount)

Contact Base Material

Phosphor Bronze

Contact Plating, Mating Area, Material

Gold (30), Gold Flash over (50) Palladium Nickel

Housing Material

GF Liquid Crystal Polymer (LCP)

Housing Color

Black

Ul Flammability Rating

UL 94V-0

Shell

With

Lightpipe

With

Rohs/elv Compliance

Not reviewed for ELV/RoHS compliance

Lead Free Solder Processes

Not reviewed for lead free solder process

High Temperature Housing

Yes

Pcb Thickness, Recommended (mm [in])

0.97 [0.038]

Packaging Method

Tray

4.

4.1.

4.2.

4.3.

4.4.

Rev O4

QUALITY ASSURANCE PROVISIONS

Qualification Testing

A.

B.

Requalification Testing

If changes significantly affecting form, fit or function are made to the product or manufacturing process,

product assurance shall coordinate requalification testing, consisting of all or part of the original testing

sequence as determined by development/product, quality and reliability engineering.

Acceptance

Acceptance is based on verification that the product meets the requirements of Figure 1. Failures

attributed to equipment, test setup or operator deficiencies shall not disqualify the product. If product

failure occurs, corrective action shall be taken and specimens resubmitted for qualification. Testing to

confirm corrective action is required before re-submittal.

Quality Conformance Inspection

The applicable quality inspection plan shall specify the sampling acceptable quality level to be used.

Dimensional and functional requirements shall be in accordance with the applicable product drawing

and this specification.

Specimen Selection

Specimens shall be prepared in accordance with applicable Instruction Sheets and shall be

selected at random from current production. Each test group shall consist of 4 specimens.

Test Sequence

Qualification inspection shall be verified by testing specimens as specified in Figure 2.

108-2462

5 of 5