BT1M-M Panduit Corp, BT1M-M Datasheet - Page 3

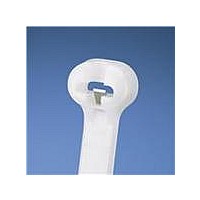

BT1M-M

Manufacturer Part Number

BT1M-M

Description

CABLE TIE 18LB NAT 4"

Manufacturer

Panduit Corp

Series

DOME-TOP® BARB-TY®r

Type

With Steel Barb Domer

Datasheets

1.DTHEH-Q0.pdf

(11 pages)

2.BT1M-M.pdf

(1 pages)

3.BT1M-M.pdf

(6 pages)

4.BT1M-M.pdf

(3 pages)

5.BT1.5I-M0.pdf

(1 pages)

Specifications of BT1M-M

Tensile Strength

18 lbs. (8.2 kg)

Length

0.333' (101.60mm, 4.00")

Color

Natural

Wire/cable Tie Type

Standard, Locking

Bundle Diameter

0.90" (22.86mm)

Width

0.095" (2.40mm)

Mounting Type

Free Hanging (In-Line)

Maximum Bundle Diameter

0.9 in

Product

Cable Ties

Application

For indoor use

Height

0.156" (Head)

Protection Class

Tie, Cable

Special Features

Locking

Cable Tie Length

4"

Cable Tie Width

0.095"

Body Material

Nylon 6.6

Tensile Strength Pounds

18lb

Cable Bundle Diameter Min

1.5mm

Cable Bundle Diameter Max

0.9"

Accessory Type

Cable Tie

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Features

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

For Use With

Cable And Wire

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Material Selection Criteria

Highest

Material

Color

Part Number Suffix

(Material Designation)

Tensile @ Yield @ 73°F (psi)

Water Absorption (24 Hours)

Radiation Resistance (Rads)

Weathering Life Expectancy

(Years)/UV Resistance

Impact Resistance

Salts

Hydrocarbons

(Oil, Lubricants)

Chlorinated Hydrocarbons

Acids

Bases

Acid Rain

Max. Continuous Use

Temperature

Min. Application Use Temperature

Flammability Rating

Low Smoke

Oxygen Index

Halogen-Free

Burning Fume Toxicity

Heat Deflection

Temperature @ 1.8 Mpa

Relative Price

Product Family

P

S

D

D

C

H

S

Elastomeric Cable Ties

AN

UPER

OME

URA

ONTOUR

YPER

TA

-S

-T

-T

-T

TRAP

Y

-G

-V

Y

®

OP

Cable Ties

RIP

-T

™

™

High

®

Cable Ties

Y

Cable Ties

®

®

Barb Ty Cable Ties BT

Cable Ties

Recommendation Legend

®

Cable Ties

Cable Ties

Acceptable

Low

CBR

SST

ERT

PLT

SG

DT

HV

BS ISO 4589

IEC 60754-2

ASTM D570

ASTM D648

ISO 75 -1/-2

ASTM E662

BSS-7239

EN 50146

UL 746B

ISO 527

Method

Lowest

UL 94

Test

—

—

—

—

—

—

—

—

—

—

—

—

Check mark indicates material availability in that product family for all cross sections.

Cross Sections: SM = Subminiature, M = Miniature, I = Intermediate, S = Standard, HS = Heavy-Standard,

Natural

Nylon 6.6

(other colors available)

No Suffix

1 x 10

12,000

185°F

158°F

-60°C

PASS

PASS

-76°F

1.2%

1 – 2

85°C

70°C

Low

Yes

V-2

28

✓

✓

✓

✓

✓

✓

LH = Light-Heavy, H = Heavy, EH = Extra-Heavy

5

SM, M, I, S

M, I, S, LH

M, I, S, HS

M, I, S, LH

Resistant

Nylon 6.6

Weather

12,000

1 x 10

M, I, S

185°F

-60°C

PASS

PASS

158°F

Black

-76°F

1.2%

7 – 9

85°C

70°C

Low

V-2

Yes

Cross Sections

28

0

5

Resistant

Nylon 6.6

LH, H, EH

Modified

Weather

Impact

1 x 10

185°F

145°F

-60°C

PASS

PASS

Black

9,700

-76°F

1.2%

7 – 9

85°C

63°C

Low

Yes

HB

LH

LH

LH

—

H

0

5

Stabilized

Nylon 6.6

12,000

1 x 10

115°C

239°F

-60°C

PASS

158°F

Black

-76°F

PASS

1.2%

4 – 5

70°C

Heat

Low

V-2

Yes

30

28

✓

✓

✓

✓

✓

✓

5

Stabilized

Nylon 6.6

Natural

1 x 10

12,000

239°F

115°C

158°F

-60°C

PASS

PASS

-76°F

1.2%

1 – 2

70°C

Heat

Low

Yes

V-2

39

28

✓

✓

✓

5

Stabilized

Resistant

Nylon 6.6

Weather

(Note 1)

12,000

1 x 10

100°C

212°F

158°F

Black

-76°F

-60°C

PASS

PASS

1.2%

7 – 9

Heat

70°C

Med

300

Yes

V-2

28

✓

✓

5

Retarda

Nylon 6

1 x 10

11,000

Flame

212°F

100°C

154°F

-40°C

PASS

PASS

Black

-40°F

1.1%

1 – 2

68°C

Med

Yes

V-0

60

34

✓