CLN6A-MKW-CJ0K0233 Cree Inc, CLN6A-MKW-CJ0K0233 Datasheet - Page 11

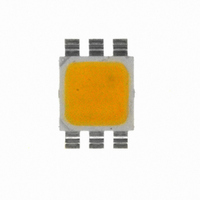

CLN6A-MKW-CJ0K0233

Manufacturer Part Number

CLN6A-MKW-CJ0K0233

Description

LED WARM WHITE 5X5MM SMD

Manufacturer

Cree Inc

Datasheet

1.CLN6A-MKW-CH0K0133.pdf

(12 pages)

Specifications of CLN6A-MKW-CJ0K0233

Viewing Angle

115°

Color

White, Warm

Current - Test

300mA

Luminous Flux @ Current - Test

65lm

Current - Max

350mA

Lumens @ Current - Max

72lm

Lumens/watt @ Current - Test

57lm/W

Voltage - Forward (vf) Typ

3.8V

Wavelength

3200K

Lens Style/size

Square, 4mm

Mounting Type

Surface Mount

Package / Case

0.2" L x 0.2" W x 0.05" H (5mm x 5mm x 1.3mm)

Led Color

Warm White

Luminous Flux @ Test

72lm

Cct

4600K

Forward Current @ Test

300mA

Forward Current If Max

600mA

Forward Voltage @ Test

3.8V

Power Dissipation Pd

1.2W

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

CLN6A-MKW-CJ0K0233TR

Soldering & Handling

1. Cleaning

• Don’t use unspecified chemical liquids to clean the SMD LED; the chemical could harm the SMD LED. When washing

• The influence of ultrasonic cleaning on the SMD LED depending on factors such as ultrasonic power and the way

2. Moisture Proof Packing

• In order to prevent moisture absorption into SMD LED during the transportation and storage, SMD LED is packed

3. Storage

• Shelf life in original sealed bag at storage condition of <40ºC and <90%RH is 12 months. Baking is required

• Before openning the packaging , Please check whether bag leak air or not.

• After bag opening, the SMD LED must be stored under the condition < 30ºC and < 60%RH. Under this condition,

• For baking, place SMD LED in oven at temperature 80ºC±5ºC and relative humidity <=10%RH, for 24 hours.

• Take out the material from packaging bag for re-bake. Do not open the door of oven frequently during the baking

4. Soldering

• Manual soldering by soldering iron

• The use of a soldering iron of less than 25W is recommended and the temperature of the iron must be kept at

• The epoxy resin of SMD LED should not be in contact with tip of soldering iron.

• No mechanical stress should be exerted on the resin portion of SMD LED during soldering.

• Handling of SMD LED should be done when the package has been cooled down to below 40ºC or less. This is to

• Reflow Soldering

• The temperature (Top surface of SMD LED) profile is as below:

Copyright © 2010 Cree, Inc. All rights reserved. The information in this document is subject to change without notice. Cree and

the Cree logo are registered trademarks of Cree, Inc.

11

Solder = Lead-free

Average ramp-up rate = 4ºC/s max

Preheat temperature = 150ºC ~200ºC

Preheat time = 100s max.

Ramp-down rate = 6ºC/s max.

is necessary, please immerse the SMD LED in alcohol at normal room temperature for less than 1 minute and dry at

normal room temperature for 15 minutes before use.

SMD LED are mounted. Ultrasonic cleaning shall be pre-qualified to ensure this will not cause damage to the SMD

LED.

in a moisture barrier bag. Desiccants and a humidity indicator are packed together with SMD LED as the secondary

protection. The indication of humidity indicator card provides the information of humidity within SMD packing.

whenever shelf life is expired.

SMD LED must be used (subject to reflow) within 168 hours after bag opening, and re-baking is required when

exceeding 168 hours.

process.

below 315ºC, with soldering time within 2 seconds.

prevent the SMD LED failures due to thermal-mechanical stress during handling.

Melting-point

CLD-CT979.004

Pre-heat

Soak

Time

Reflow

Cooling

Peak temperature = 250ºC max.

Time within 5ºC of actual Peak Temperature = 10s max.

Duration above 217ºC is 80s max.

Heat Sink

USA Tel: +1.919.313.5300

www.cree.com/ledlamps

Fax: +1.919.313.5778

Durham, NC 27703

4600 Silicon Drive

Cree, Inc.