HLMP-2965 Avago Technologies US Inc., HLMP-2965 Datasheet - Page 16

HLMP-2965

Manufacturer Part Number

HLMP-2965

Description

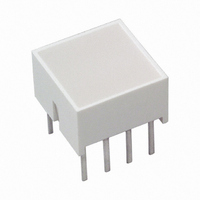

LED LT BAR 8.89X8.89MM HER/GRN

Manufacturer

Avago Technologies US Inc.

Datasheet

1.HLMP-2500.pdf

(16 pages)

Specifications of HLMP-2965

Color

Green, Red

Voltage Rating

2.2V Green, 2.0V Red

Current

30mA

Lens Style/size

Square, 8.89mm

Configuration

Single

Mounting Type

Through Hole

Product

LED Light Bars

Illumination Color

Red, Green

Luminous Intensity

45 mcd

Light Bar Length

8.89 mm

Supply Voltage

2 V

Supply Current

20 mA

Wavelength

626 nm

Led Configuration

Bar

Led Color

Red / Green

Forward Voltage / Color

R 2V / G 2.2V

No. Of Leds

2

Luminous Intensity / Color

R 45mcd / G 50mcd

Forward Current If

20mA

Rohs Compliant

Yes

Display Size

8.89mm X 8.89mm

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lens Type

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

516-1259-5

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

HLMP-2965

Manufacturer:

AVAGO

Quantity:

40 000

Example:

The time average luminous

intensity may be adjusted for

operating ambient temperature by

the following exponential

equation:

I

For product information and a complete list of distributors, please go to our website:

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies Limited in the United States and other countries.

Data subject to change. Copyright © 2006 Avago Technologies Limited. All rights reserved. Obsoletes 5988-2221EN

AV01-0692EN December 9, 2006

v

I

= 14 mcd.

AlGaAs Red

HER

Yellow

Green

v

(T

(80 C) = (25 mcd)e

A

Color

) = I

V

(25 C)e

–0.0095/ C

–0.0131/ C

–0.0112/ C

–0.0104/ C

[K (T –25 C)]

K

A

[-0.0112 (80-25)]

Mechanical

These light bar devices may be

operated in ambient temperatures

above +60 C without derating

when installed in a PC board

configuration that provides a

thermal resistance pin to ambient

value less than 280 C/W/LED. See

Figure 2 or 7 to determine the

maximum allowed thermal

resistance for the PC board,

R

nonderated operation in a given

ambient temperature.

To optimize device optical

performance, specially developed

plastics are used which restrict

the solvents that may be used for

cleaning. It is recommended that

only mixtures of Freon (F113)

and alcohol be used for vapor

cleaning processes, with an

PC-A

, which will permit

www.avagotech.com

immersion time in the vapors of

less than two (2) minutes

maximum. Some suggested vapor

cleaning solvents are Freon TE,

Genesolv DES, Arklone A or K. A

60 C (140 F) water cleaning

process may also be used, which

includes a neutralizer rinse (3%

ammonia solution or equivalent),

a surfactant rinse (1% detergent

solution or equivalent), a hot

water rinse and a thorough air

dry. Room temperature cleaning

may be accomplished with Freon

T-E35 or T-P35, Ethanol,

Isopropanol or water with a mild

detergent.

For further information on

soldering LEDs please refer to

Application Note 1027.