LM5025EVAL National Semiconductor, LM5025EVAL Datasheet

LM5025EVAL

Specifications of LM5025EVAL

*LM5025EVAL/NOPB

LM5025EVAL

Related parts for LM5025EVAL

LM5025EVAL Summary of contents

Page 1

... Watts. The operation of the trans- former in a forward topology does not inherently self-reset each power switching cycle, a mechanism to reset the trans- former is required. The active clamp reset mechanism is © 2004 National Semiconductor Corporation National Semiconductor Application Note 1345 Robert Bell ...

Page 2

Theory of Operation Powering and Loading Considerations When applying power to the LM5025A evaluation board certain precautions need to be followed. A failure or mis- connection can present itself in a very alarming manner. Proper Connections When operated at low ...

Page 3

Powering Up (Continued) the wattage of the load. As you remove the connection from the shutdown pin to ground, immediately check for 3.3 volts at the output. A most common occurrence, that will prove unnerving, is when the current limit ...

Page 4

Performance Characteristics TURN-ON WAVEFORMS When applying power to the LM5025A evaluation board a certain sequence of events must occur. Soft-start capacitor values and other components allow the feedback loop to stabilize without overshoot. Figure 1 shows the output volt- age ...

Page 5

Performance Characteristics (Continued) Conditions: Input Voltage = 78VDC Output Current = 25A Trace 1: Q1 drain voltage Volts/div = 20V Horizontal Resolution = 1µs/div FIGURE 5. Conditions: Input Voltage = 48VDC Output Current = 5A Synchronous rectifier, Q3 gate Volts/div ...

Page 6

www.national.com 6 ...

Page 7

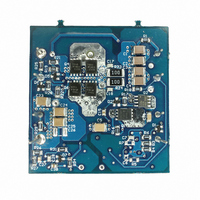

Layout and Bill of Materials The Bill of Materials is shown below and includes the manu- facturer and part number. The layers of the printed circuit board are shown in top down order. View is from the top Bill of ...

Page 8

Layout and Bill of Materials Bill of Materials (Continued) DESIGNATOR QTY R9,R10 R11 1 R12,R15,R18,R26 4 R13 1 R14 1 R23,R24 2 R27 1 R28 1 R30 ...

Page 9

PCB Layouts 20127610 9 www.national.com ...

Page 10

PCB Layouts (Continued) www.national.com 20127611 10 ...

Page 11

PCB Layouts (Continued) 20127612 11 www.national.com ...

Page 12

PCB Layouts (Continued) www.national.com 20127613 12 ...

Page 13

PCB Layouts (Continued) 20127614 13 www.national.com ...

Page 14

... BANNED SUBSTANCE COMPLIANCE National Semiconductor certifies that the products and packing materials meet the provisions of the Customer Products Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification (CSP-9-111S2) and contain no ‘‘Banned Substances’’ as defined in CSP-9-111S2. ...