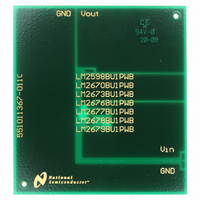

551011367-011/NOPB National Semiconductor, 551011367-011/NOPB Datasheet - Page 28

551011367-011/NOPB

Manufacturer Part Number

551011367-011/NOPB

Description

BOARD WEBENCH BUILD IT LM2598

Manufacturer

National Semiconductor

Series

WEBENCH® Buildit Boardr

Datasheet

1.LM2598T-12NOPB.pdf

(33 pages)

Specifications of 551011367-011/NOPB

Main Purpose

DC/DC, Step Down

Regulator Topology

Buck

Board Type

Bare (Unpopulated)

Utilized Ic / Part

LM2598, LM2670, LM2673, LM2676, LM2677, LM2678, LM2679

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Current - Output

-

Voltage - Output

-

Voltage - Input

-

Power - Output

-

Frequency - Switching

-

Outputs And Type

-

Other names

*551011367-011

*551011367-011/NOPB

551011367-011

*551011367-011/NOPB

551011367-011

www.national.com

Application Information

lNVERTING REGULATOR

The circuit in Figure 27 converts a positive input voltage to a

negative output voltage with a common ground. The circuit

operates by bootstrapping the regulators ground pin to the

negative output voltage, then grounding the feedback pin,

the regulator senses the inverted output voltage and regu-

lates it.

This example uses the LM2598-5 to generate a −5V output,

but other output voltages are possible by selecting other

output voltage versions, including the adjustable version.

Since this regulator topology can produce an output voltage

that is either greater than or less than the input voltage, the

maximum output current greatly depends on both the input

and output voltage. The curve shown in Figure 28 provides a

guide as to the amount of output load current possible for the

different input and output voltage conditions.

The maximum voltage appearing across the regulator is the

absolute sum of the input and output voltage, and this must

be limited to a maximum of 40V. In this example, when

converting +20V to −5V, the regulator would see 25V be-

tween the input pin and ground pin. The LM2598 has a

maximum input voltage rating of 40V.

An additional diode is required in this regulator configuration.

Diode D1 is used to isolate input voltage ripple or noise from

coupling through the C

or no load conditions. Also, this diode isolation changes the

topology to closely resemble a buck configuration thus pro-

viding good closed loop stability. A Schottky diode is recom-

mended for low input voltages, (because of its lower voltage

drop) but for higher input voltages, a 1N5400 diode could be

used.

Because of differences in the operation of the inverting

regulator, the standard design procedure is not used to

select the inductor value. In the majority of designs, a 68 µH,

1.5 Amp inductor is the best choice. Capacitor selection can

also be narrowed down to just a few values. Using the values

shown in Figure 27 will provide good results in the majority of

inverting designs.

This type of inverting regulator can require relatively large

amounts of input current when starting up, even with light

loads. Input currents as high as the LM2598 current limit

(approximately 1.5A) are needed for 2 ms or more, until the

output reaches its nominal output voltage. The actual time

depends on the output voltage and the size of the output

capacitor. Input power sources that are current limited or

sources that can not deliver these currents without getting

FIGURE 28. Maximum Load Current for Inverting

Regulator Circuit

IN

capacitor to the output, under light

DS012593-44

(Continued)

28

loaded down, may not work correctly. Because of the rela-

tively high startup currents required by the inverting topology,

the Soft-start feature shown in Figure 27 is recommended.

Also shown in Figure 27 are several shutdown methods for

the inverting configuration. With the inverting configuration,

some level shifting is required, because the ground pin of the

regulator is no longer at ground, but is now at the negative

output voltage. The shutdown methods shown accept

ground referenced shutdown signals.

UNDERVOLTAGE LOCKOUT

Some applications require the regulator to remain off until

the input voltage reaches a predetermined voltage. Figure

29 contains a undervoltage lockout circuit for a buck configu-

ration, while Figure 30 and Figure 31 are for the inverting

types (only the circuitry pertaining to the undervoltage lock-

out is shown). Figure 29 uses a zener diode to establish the

threshold voltage when the switcher begins operating. When

the input voltage is less than the zener voltage, resistors R1

and R2 hold the Shutdown /Soft-start pin low, keeping the

regulator in the shutdown mode. As the input voltage ex-

ceeds the zener voltage, the zener conducts, pulling the

Shutdown /Soft-start pin high, allowing the regulator to begin

switching. The threshold voltage for the undervoltage lockout

feature is approximately 1.5V greater than the zener voltage.

Figure 30 and Figure 31 apply the same feature to an

inverting circuit. Figure 30 features a constant threshold

voltage for turn on and turn off (zener voltage plus approxi-

mately one volt). Since the SD /SS pin has an internal 7V

zener clamp, R2 is needed to limit the current into this pin to

approximately 1 mA when Q1 is on. If hysteresis is needed,

the circuit in Figure 31 has a turn ON voltage which is

different than the turn OFF voltage. The amount of hyster-

esis is approximately equal to the value of the output

voltage.

FIGURE 29. Undervoltage Lockout for a Buck

FIGURE 30. Undervoltage Lockout Without

Hysteresis for an Inverting Regulator

Regulator

DS012593-45

DS012593-47