HMC1023-PCB Honeywell Microelectronics & Precision Sensors, HMC1023-PCB Datasheet - Page 4

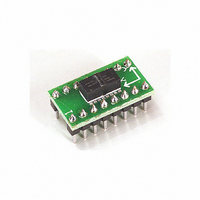

HMC1023-PCB

Manufacturer Part Number

HMC1023-PCB

Description

BOARD EVALUATION W/HMC1023 SENS

Manufacturer

Honeywell Microelectronics & Precision Sensors

Datasheet

1.HMC1023-PCB.pdf

(7 pages)

Specifications of HMC1023-PCB

Rohs Status

RoHS non-compliant

Other names

342-1007

HMC1023 DEMO KIT

HMC1023 DEMO KIT

HMC1023

SENSOR PRODUCTS

Mounting Considerations

When mounting the Honeywell HMC1023 on a circuit board, please consider the following advice for ball grid array

component attachment.

Ball Grid Array attachment/removal to printed circuit boards is precisely controlled thermal solder reflow process. To

prevent internal electrical damage and package cracking, do not use conventional soldering iron/solder station tools. If

you do not have experience and the reflow oven, please have a qualified BGA rework technician do the work for you.

The reflow profile show below is the recommended profile for HMC1023 package attachment.

Melting temperature for the HMC1023 balls is at 180°C. The recommended rise and fall temperatures should be no

greater than 3°C/sec to prevent mechnical stresses or “popcorning”. Peak external temperature the part should be

exposed to is between 200 to 210°C. When exposed a high temperature, such as the solder reflow process, the

internal connections in the package could sustain permanent damage, leaving open connections. 225°C is the melting

point of solder inside the HMC1023 Ball Grid Array package. Do not expose the part to this level of temperature.

If using solder paste, we recommend Kester SN62 solder paste with water soluble flux R560. This has a melting point

around 180°C. Kester recommends a pre-heating zone from ambient temperature to 180°C for 2 to 4 minutes

maximum. The first part of this pre-heating zone ramps up from ambient to 150°C in 90 seconds with a ramp rate of

less than 2.5 degrees C per second. The soak zone should last from 60 to 90 seconds (2 minutes maximum) and

ramp up in temperature from 150 to 180°C at 0.5 to 0.6 °C/ sec. The reflow zone should last for 30 to 90 seconds

maximum (40 to 60 seconds is ideal) and peak in temperature between 200 and 210°C with a ramp of 1.3 to

1.6°C/sec.

The reflow parameters can vary significantly and excellent reflow results can still be achieved. A thin layer of paste

flux or a 2 to 3 mil layer of solder paste applied to the mother-board prior to placing the HMC1023 is helpful. The

profile can be verified by placing a thermocouple between the HMC1023 and motherboard.

Solid State Electronics Center • www.magneticsensors.com • (800) 323-8295 • Page 4