GCM1555C1H221JA16D Murata, GCM1555C1H221JA16D Datasheet - Page 23

GCM1555C1H221JA16D

Manufacturer Part Number

GCM1555C1H221JA16D

Description

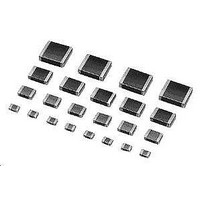

Multilayer Ceramic Capacitors (MLCC) - SMD/SMT 0402 220pF 50volts C0G +/-5%

Manufacturer

Murata

Series

GCMr

Datasheets

1.GCM188R71C105KA64D.pdf

(50 pages)

2.GCM1555C1H221JA16D.pdf

(2 pages)

3.GCM1555C1H221JA16D.pdf

(1 pages)

Specifications of GCM1555C1H221JA16D

Voltage Rating

50 Volts

Operating Temperature Range

- 55 C to + 125 C

Temperature Coefficient / Code

C0G (NP0)

Product

Automotive MLCCs

Dimensions

0.5 mm W x 1 mm L x 0.5 mm H

Dissipation Factor Df

0.01

Termination Style

SMD/SMT

Capacitance

220 pF

Tolerance

5 %

Package / Case

0402 (1005 metric)

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

GCM1555C1H221JA16D

Manufacturer:

MURATA

Quantity:

640 000

!Note

• This PDF catalog is downloaded from the website of Murata Manufacturing co., ltd. Therefore, it’s specifications are subject to change or our products in it may be discontinued without advance notice. Please check with our

• This PDF catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

sales representatives or product engineers before ordering.

!Note

Chip monolithic ceramic capacitors (chips) can

experience degradation of termination solderability

when subjected to high temperature or humidity, or if

exposed to sulfur or chlorine gases.

Storage environment must be at an ambient temperature

of 5-40 degree C and an ambient humidity of 20-70%RH.

Use chip within 6 months. If 6 months or more have

elapsed, check solderability before use.

Insulation Resistance should be deteriorated on specific

condition of high humidity or incorrosion gas such as

hydrogen sulfide, sulfurous acid gas, chlorine. Those

condition are not suitable for use.

1. Inspection

2. Board Separation (or depanalization)

(1) Board flexing at the time of separation causes

(2) Severity of stresses imposed on the chip at the

(3) Board separation must be performed using special

!Caution (Storage and Operating Condition)

!Caution (Handling)

Thrusting force of the test probe can flex the PCB,

resulting in cracked chips or open solder joints.

Provide support pins on the back side of the PCB to

prevent warping or flexing.

cracked chips or broken solder.

time of board break is in the order of:

Pushback<Slitter<V Slot<Perforator.

jigs, not with hands.

• Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

Use of Sn-Zn based solder will deteriorate

reliability of MLCC.

Please contact murata factory for the use of Sn-Zn

based solder in advance.

Do not use under the condition that causes

condensation. Use dampproof countermeasure if using

under the condition that causes condensation.

FAILURE TO FOLLOW THE ABOVE CAUTIONS MAY

RESULT, WORST CASE, IN A SHORT CIRCUIT

AND CAUSE FUMING OR PARTIAL DISPERSION

WHEN THE PRODUCT IS USED.

3. Reel and bulk case

FAILURE TO FOLLOW THE ABOVE CAUTIONS MAY

RESULT, WORST CASE, IN A SHORT CIRCUIT

AND FUMING WHEN THE PRODUCTS IS USED.

In the handling of reel and case, please be careful

and do not drop it.

Do not use chips from a case which has been dropped.

!Caution

C03E.pdf

21

09.3.31

1